A research team led by Associate Professor Xin Xiao from Donghua University’s College of Environmental Science and Engineering has achieved a significant breakthrough in the development of intelligent temperature-regulating fabrics using phase change microcapsules. Their study, “Study on intelligent temperature regulating fabric based on phase change microcapsules of bio-based eutectic system,” has been published in Applied Thermal Engineering, a journal ranked CAS Tier 1 in Thermodynamics and Tier 2 in general subjects. The paper’s co-first authors are Yaqi Niu and Yueyue Ma, both 2022 undergraduate students majoring in Energy and Environmental Engineering with their classmates Jijuan Zhao, Congyue Xu, and Nadiya Amankelde contributing as co-authors.

The study tackles two urgent global issues: the high energy consumption of the construction sector and the heavy carbon emissions associated with conventional textile production. To address these challenges, the team created an innovative intelligent fabric that integrates phase change microcapsules capable of absorbing, storing, and releasing heat.

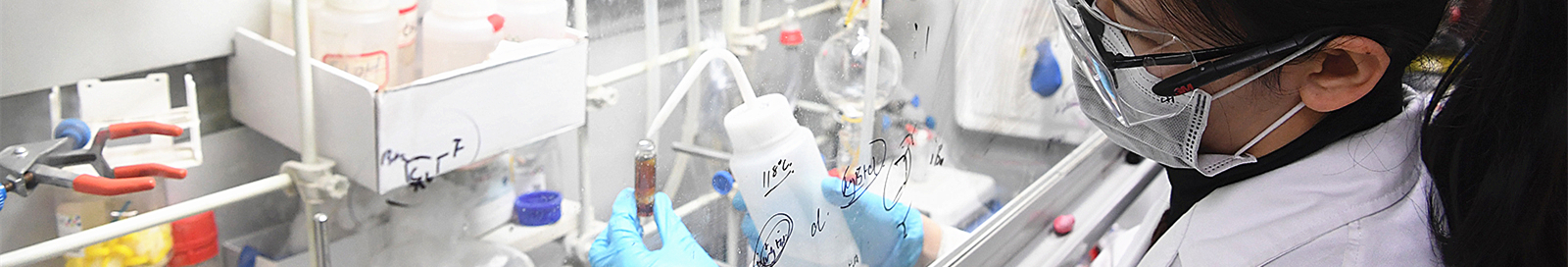

The process involves using a bio-based eutectic mixture of lauric acid (LA) and myristic acid (MA) as the microcapsule core, forming a silica (SiO₂) inorganic shell via a water-based sol-gel method, and then applying the microcapsules to fabric through dip-printing. The resulting fabric balances high thermal performance with durability and comfort, while also advancing eco-friendly, cost-effective textile manufacturing. Its potential spans from daily wear and outdoor gear to spacesuits, protective apparel, and even applications in building energy-efficiency, a step toward low-carbon innovation across industries.

The research delivers four notable breakthroughs. Firstly, the team replaced petroleum-based core materials with bio-based alternatives and substituted toxic silicon sources like TEOS with acidic silica sol. Combined with the water-based sol-gel process, this significantly reduces environmental impact across the entire microcapsule fabrication chain. Secondly, by engineering a eutectic LA–MA system, the team fine-tuned the phase change temperature to a human-friendly range—melting at 36.63 °C and crystallizing at 32.50 °C—while maintaining high latent heat. This overcomes the mismatch issues of single-fatty-acid systems and enhances comfort during real-world temperature fluctuations. Thirdly, the use of hydrophobic inorganic shells in place of conventional organic ones significantly enhances overall performance: thermogravimetric analysis shows a mass loss of less than 2.5% at 300 °C, while leakage tests indicate a rate below 0.01% at 100 °C. These results demonstrate marked improvements in the microcapsules’ mechanical strength, thermal stability, and resistance to leakage. Finally, the microcapsules exhibit a uniform spherical core-shell structure with an average diameter of 1.27 μm. Combined with improved dip-printing techniques, the researchers produced fabrics with exceptional temperature-regulating capabilities—achieving a thermal hysteresis efficiency of 500% and cooling efficiency of 105%—without compromising softness or wearability.

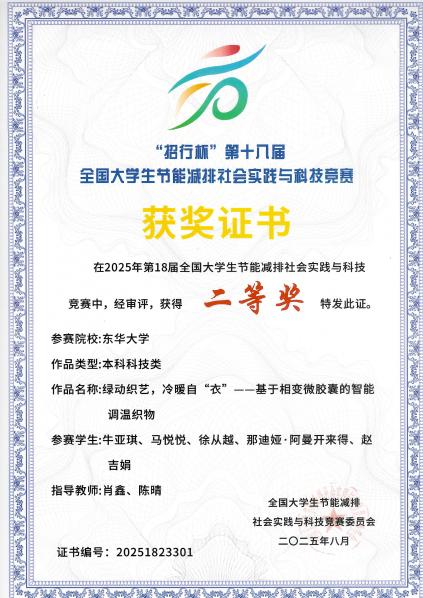

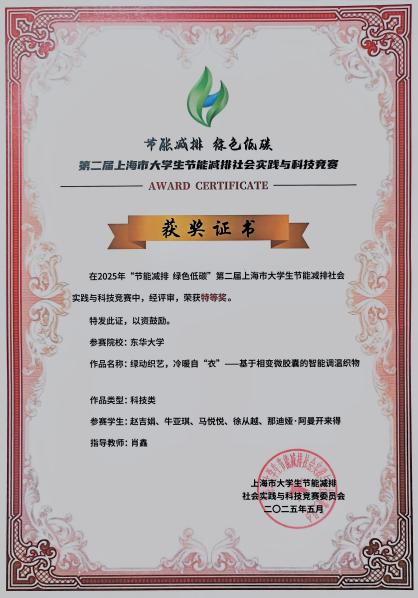

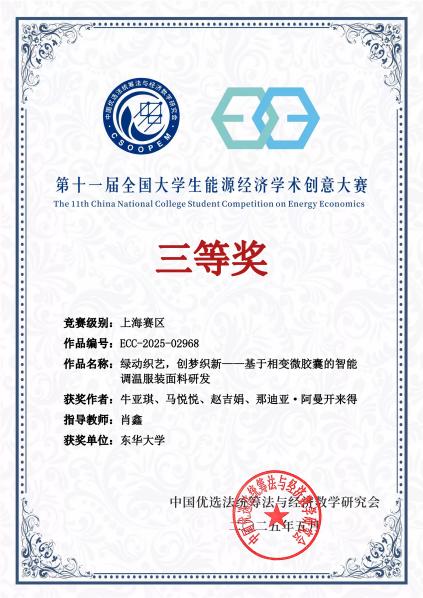

Beyond the student researchers’ dedicated efforts, Professor Qing Chen from the International Fashion Center and the College of Fashion and Design provided crucial material support that ensured the project progressed smoothly. The paper was completed under the National College Student Innovation and Entrepreneurship Training Program, where it received an excellent rating. The team has already earned multiple national and provincial honors for related work, including National Second Prize, National College Student Energy Conservation and Emission Reduction Competition; Special Prize, 2nd Shanghai College Student Energy Conservation and Emission Reduction Social Practice and Technology Competition; and Provincial Third Prize, 11th National College Student Energy Economics Academic Innovation Competition. These achievements underscore the team’s strong innovation capacity and the real-world value of their research, which stands poised to support China’s transition toward smarter, greener, low-carbon textile technologies.

(Award Records)

Source: https://doi.org/10.1016/j.applthermaleng.2025.128726