Passive radiative cooling fabrics offer a sustainable way to reduce energy consumption in thermal management, yet their reliance on petroleum-derived materials and complex coating processes compromises both environmental compatibility and wearability. Cellulose, as an ideal alternative material, demonstrates significant advantages due to its renewable sources, biodegradability, and intrinsic infrared activity from C−O−C/C−O vibrational bands within 8−13 μm. Therefore, through integrating cellulose with skin-wrinkle-inspired structural design, a balance between optical performance, wearer comfort, and scalable manufacturing can be achieved.

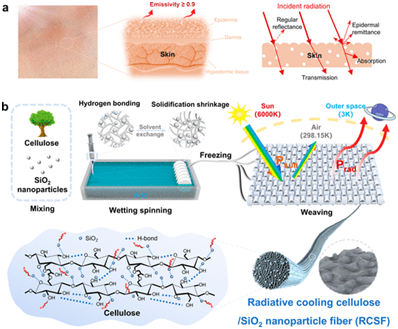

Recently, the research team led by Researcher Kong Weiqing and Professor Zhu Meifang from the College of Materials Science and Engineering and the State Key Laboratory for Advanced Fiber Materials, DHU drew inspiration from the multilayered structure and thermoregulatory mechanism of human skin to design cellulose/SiO₂ nanoparticle radiative fibers (RCSF) resembling skin-wrinkle structure (Figure 1).

Figure 1. Bioinspired design and scalable fabrication of RCSF

The RSCF surface displays unique skin-wrinkle-like protrusions (height ≈ 2.0 μm), with a micro-nano hierarchical roughness four times greater than that of the pristine RCF.

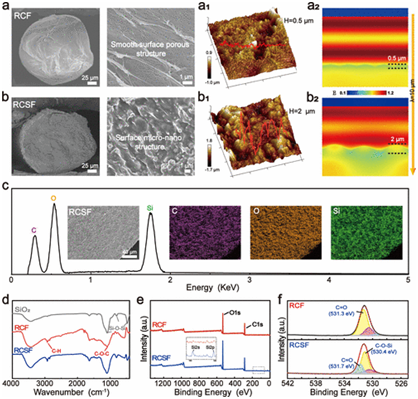

This synergistic structure not only significantly enhances the scattering efficiency of sunlight but also effectively optimizes the fiber absorption and emissivity rate of mid-infrared radiation due to the increased surface area and the creation of a cavity structure, thereby enhancing radiative cooling performance. Research shows that SiO₂ nanoparticles are firmly bonded to the cellulose matrix via hydrogen bonds, constituting a stable micro-nano hierarchical structure (Figure 2).

Figure 2. Morphological and structural characterization of RCSF

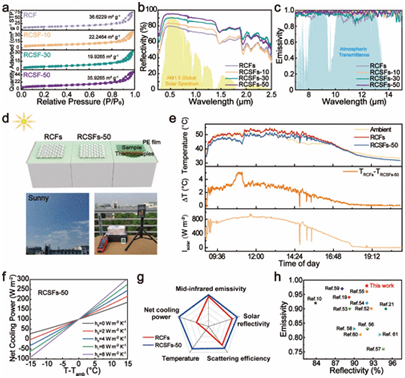

Through optical and outdoor performance tests(Figure 3), RCSF demonstrates excellent radiative cooling performance, achieving a synergy of high solar reflectivity (93.7%) and high infrared emissivity (0.98). Simultaneously, it achieves a net cooling power of 100.1 W/m² under 800 W/m² solar irradiation outdoors, leading to a 5 °C temperature reduction compared with regenerated cellulose fibers (RCF).

RCSFs-50 fabrics exhibits outstanding comprehensive performance in application. Under controlled indoor conditions, RCSFs-50 maintains a temperature of 3.39°C, demonstrating a 139% improvement in cooling effect compared to cotton fabric. During outdoor use, its surface temperature remains consistently 5°C lower than the body surface temperature. Its air permeability is 9.5 times that of polyester and 1.73 times that of cotton, with moisture permeability comparable to cotton. Under 865 W/m² solar irradiation, its temperature is 5.8°C and 9.1°C lower than cotton and polyester respectively. After ten laundering and abrasion cycles, it maintains 97.6% of its cooling efficiency, demonstrating excellent durability (Figure 4), laying a solid foundation for the development of sustainable outdoor cooling textiles.

Figure 3. Optical characteristics and outdoor test performance of RCSF

Figure 4. Wearing performance

Doctoral student Li Qihua from the College of Materials Science and Engineering, DHU is the first author of the paper. The corresponding author is Associate Researcher Kong Weiqing. The related findings were recently published in ACS Nano titled Eco-Friendly Skin-Wrinkle-Inspired Micro-Nano Structured Cellulose Composite Fibers for Highly Efficient Daytime Radiative Cooling. This work was financially supported by Shanghai Oriental Talents Youth Program.