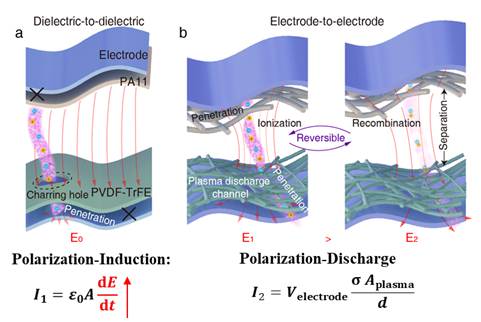

The story of electricity begins with polarization. When humans first observed that rubbed amber can attract scraps, the essence of electricity was revealed as the imbalance of charges within materials. As research deepened, it was understood that charge separation stems from differences in electron affinity between materials and the polarization response of dielectrics. When external mechanical force or electric field disturbances alter the polarization distribution within a dielectric, a potential difference arises inside the system, thereby driving charge migration and energy conversion. Based on this principle, electrostatic induction provides a pathway for energy release during polarization, forming the core framework for energy harvesting in electrostatic energy harvesters such as triboelectric nanogenerators, piezoelectric generators, and pyroelectric systems. However, this type of energy conversion relies on the synergistic response of dielectric polarization and charge migration. Its dynamic process is limited by interface charging/discharging and dielectric relaxation time, resulting in limited output current, which becomes a bottleneck for improving the power density of electrostatic energy harvesting.

Recently, the research team led by Professor Wang Hongzhi and Researcher Hou Chengyi from the State Key Laboratory of Advanced Fiber Materials and the College of Materials Science and Engineering, DHU, proposed an energy release mechanism based on electrostatic breakdown and accordingly developed a Plasma-Enabled Energy Textile (PEET). This research revealed a previously overlooked efficient energy transfer pathway between dielectric polarization and electrostatic induction: engineering plasma-treated discharge microchannels through controllable dielectric breakdown, and transforming the slow displacement current into a fast conduction current to achieve rapid energy release and efficient conversion.

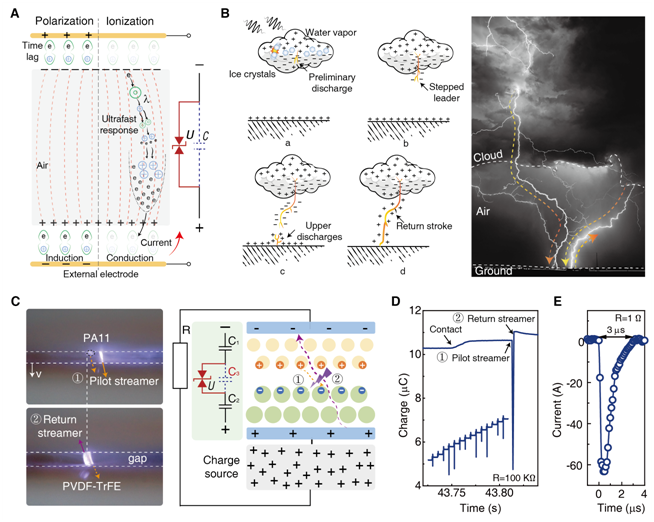

Inspired by the natural lightning discharge, the researchers simulated its “return stroke” mechanism. In natural lightning, once a conductive channel forms, charge rapidly flows back along the existing path, releasing enormous energy. The team introduced this concept into the textile structure, constructing stable plasma microchannels between fibers to achieve repeatable and controllable discharge paths. The plasma channel exhibits a “memory effect” after discharge, significantly lowering the breakdown threshold, enabling the system to achieve stable discharge and energy release under lower external fields.

Figure 1. Stable and controllable electrostatic breakdown via a plasma memory effect that stimulates lightning return strokes

Thus, electric field breakdown is redefined as a utilizable and controllable energy release mechanism. Through precise design of the discharge threshold and channel morphology, plasma periodically forms and dissipates on the dielectric surface, avoiding material damage while achieving stable energy transfer. Experimental results show that this design effectively reduces the equivalent impedance of the dielectric layer, lowering the output characteristics from the meg-ohm level to the ohm level. Under 2 Hz low-frequency mechanical excitation, the PEET achieved a current density of 2.5 A·cm⁻² and an energy conversion efficiency of 19%, representing an improvement of two orders of magnitude compared to traditional triboelectric and piezoelectric systems.

Figure 2. Dependence of the “polarization-induction” and “polarization-discharge” energy conversion frameworks on electric field variation rate and plasma conductivity respectively

The plasma-enabled energy textile holds broad potential value in application. Its high current output and low impedance characteristics enable it to directly drive flexible sensors, wearable electronics, or wireless communication modules, offering new solutions for self-powered electronic textiles. Simultaneously, the local plasma effects within the textile structure can be extended to other functional areas, such as achieving antibacterial, anti-fouling, and self-cleaning functions on fabric surfaces via low-temperature plasma, or integrating with physiological signal sensing for dynamic monitoring of blood flow, myoelectricity, and respiration. The research team indicated that they will continue to explore the stability and biosafety of PEET in complex physiological environments, and further optimize discharge control and energy management mechanisms through strategies such as magnetic control and electric field feedback.

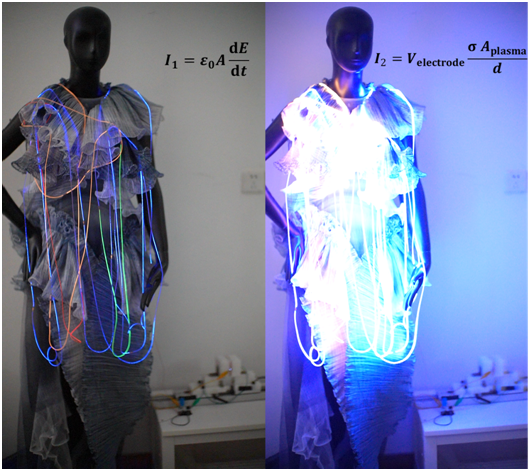

Figure 3. Comparison of the luminescence of optoelectronic fibers driven by displacement current versus conduction current

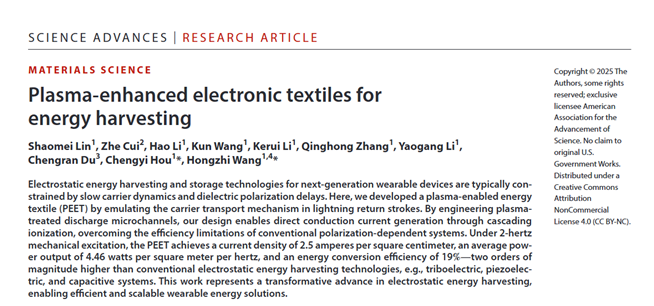

The research result was published in the academic journal Science Advances titled Plasma-enhanced electronic textiles for energy harvesting (Sci. Adv. 2025, 11, eadx2628., DOI:10.1126/sciadv.adx2628). The first author is Lin Shaomei, a DHU PhD student, with Professor Wang Hongzhi and Researcher Hou Chengyi as corresponding authors. This research received funding from the National Natural Science Foundation of China and DHU Distinguished Young Professor Program, among other sources.