Recently, a DHU research team successfully developed high-efficiency and stable all-Mg-based thermoelectric devices composed of p-type MgAgSb and n-type Mg3(Sb,Bi)2. The device performance remained stable after operating for 1,440 hours in the temperature range from nearroom-temperature to 573 K, breaking through the bottleneck of easy failure of traditional thermoelectric interfaces and providing a new approach for developing high-performance, long-life thermoelectric devices. The related research results, titled Atomic-scale interface strengthening unlocks efficient and durable Mg-based thermoelectric devices, were published inNature Materials. Corresponding authors of the paper are Professor JiangWan and Professor WangLianjun from the State Key Laboratory of Advanced Fiber Materials and the College of Materials Science and Engineering, DHU, Professor Zhang Qihao from the Institute of Functional Materials at DHU, and Researcher Xu Fangfang from Shanghai Institute of Ceramics, Chinese Academy of Sciences. ZuoWusheng, a PhD student from the College of Materials Science and Engineering at DHU, class of 2021, is the first author. Professor Chen Hongyi from Central South University, Dr. Yu Ziyi from Shanghai Institute of Ceramics, Chinese Academy of Sciences, and FuYuntian, a PhD student from the College of Materials Science and Engineering, class of 2020, are co-first authors. This work was financially supported by the National Natural Science Foundation of China, the Innovation Program of Shanghai Municipal Education Commission, Shanghai Committee of Science and Technology, and some other programs.

Breaking Through the Interface Stability Bottleneck to Achieve AHigh Thermoelectric Conversion Efficiency

Thermoelectric devices, based on the Seebeck effect, enable direct conversion of heat into electricity, with unique advantages such as no noise, small size, and maintenance-free operation, showing broad application prospects in harnessing waste heat from decentralized sources. However, for a long time, elemental diffusion and chemical reactions have been prone to occur at the electrode-thermoelectric material interface during high-temperature operation of thermoelectric devices, severely limiting their stability and widespread application. Therefore, how to construct highly stable interfaces that can suppress elemental diffusion and chemical reactions to achieve long-term reliable thermoelectric conversion has become one of the core challenges in the development of thermoelectric materials and devices.

This study proposes an atomic-scale interface strengthening strategy. By regulating interfacial chemical bonding and diffusion, the team successfully fabricated efficient and stable all-Mg-based thermoelectric devices. Experiments show that devices with the atomic-scale interface design maintained stable conversion efficiency after undergoing 600 complete thermal cycles (cumulatively 1,440 hours) within the hot-side temperature range from 373 K to 573 K, far exceeding devices with traditional interface designs. This research not only maintains the interface stability but also provides a new technical route for the long-term service of high-performance thermoelectric devices.

Atomic Interface: Enhancing Interfacial Bonding Strength and Electrical Properties

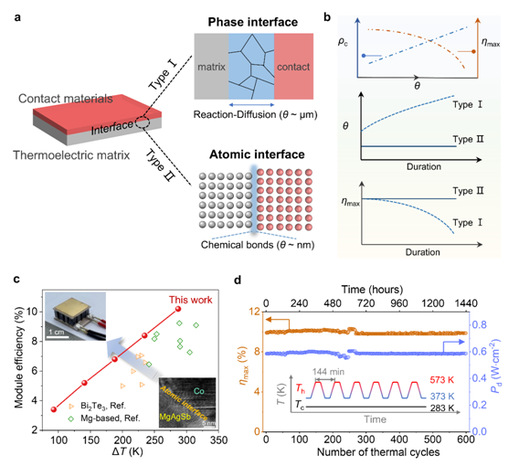

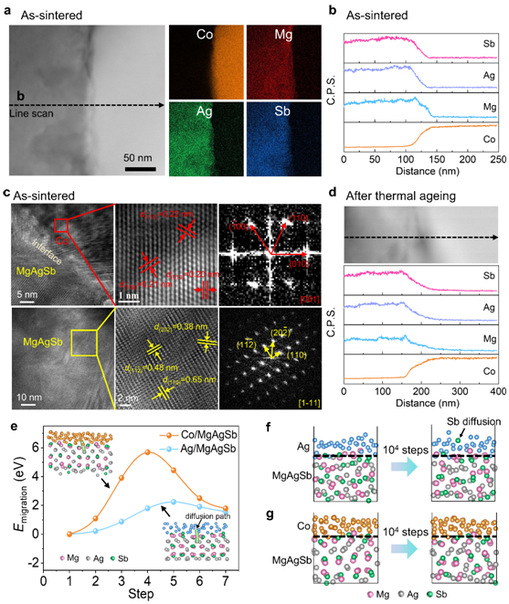

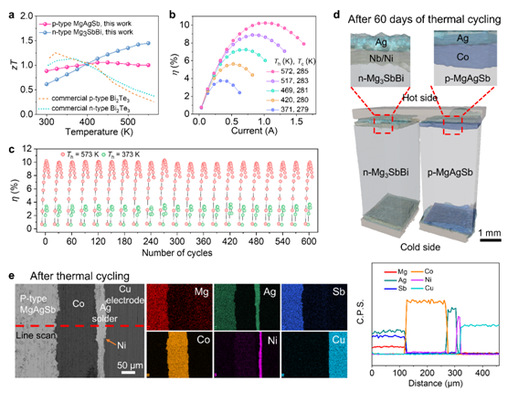

By comparing the microstructures of traditional phase interfaces and the new atomic-scale interfaces (Fig. 1a,b), the research team revealed for the first time the significant enhancement of stability of the atomic-scale interface. The device exhibited excellent thermoelectric conversion performance under different temperature differences, with efficiency significantly higher than existing Mg-based/Bi2Te3-based devices (Fig. 1c). Meanwhile, during long-term service testing at 573 K, the interface structure remained stable with no significant elemental diffusion, demonstrating the enhancement of the atomic-scale interface on device stability (Fig. 1d).

Fig. 1 (a,b) Atomic interface design for highly stable thermoelectric devices. (c) Comparison of the conversion efficiency of the MgAgSb/Mg3SbBi module with those of previously reported Mg-based modules at different temperature differences. (d) Thermal cycling reliability assessment of the all-Mg-based thermoelectric module.

Innovative High-Throughput Screening Approach for Precise Optimization of Interface Materials

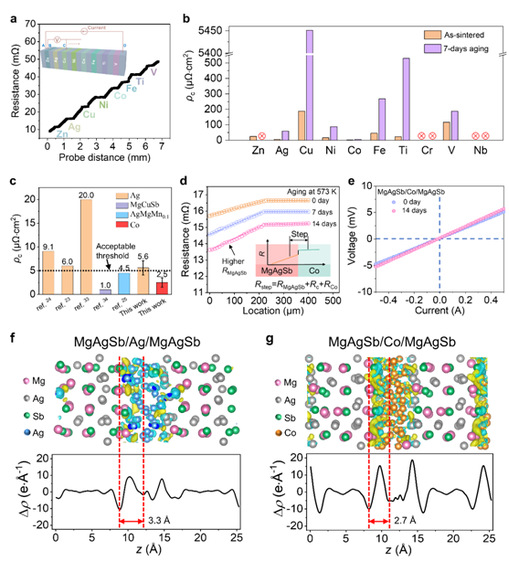

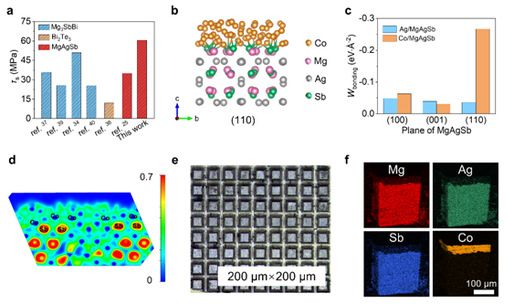

To address the issue of interfacial diffusion between thermoelectric materials and metal electrodes, the research team innovatively developed a high-throughput screening approach of barrier layers (Fig. 2), significantly improving the efficiency of barrier layer material screening. This method utilizes multi-interface simultaneous construction technology, enabling the formation of multiple heterogeneous interfaces and parallel resistance testing in a single sintering process, greatly enhancing experimental efficiency. The study found that as a barrier layer material, cobalt (Co)exhibits outstanding interfacial properties: it not only has extremely low contact resistivity (stability before and after ageing <5 µΩ·cm²) but also shows no obvious elemental diffusion after long-term service. Compared to the traditional silver (Ag) barrier layer, the Co barrier layer demonstrates superior interfacial stability and bonding strength (Fig. 3), providing important guidance for interface optimization in thermoelectric devices.

Fig. 2 (a, b, c) The contact resistivity of high-throughput screening of barrier layers and comparison with literature. (d, e)Comparison of contact resistivity for the Co/MgAgSb interface before and after ageing. (f, g)Charge density difference of different barrier layers.

Fig. 3 (a-d)Interface characterization of the Co/MgAgSb element before and after ageing. (e, f)Molecular dynamics simulations of Ag and Co as barrier layers

Enhancing Bonding Strength to Realize High Conversion Efficiency and Reliability of Thermoelectric Devices

Further research showed that the Co barrier layer can form an atomic-scale direct bonding interface with MgAgSb, effectively enhancing the interfacial bonding strength (Fig. 4). Shear strength tests revealed that an average shear strength of the as-sintered Co/MgAgSb junctions reaches 60.6 MPa, surpassing that of the traditional Ag barrier layer. Micromachining tests further confirmed that this interface can effectively withstand mechanical stress changes during high-temperature service, ensuring the long-term stable operation of the device.

Based on the selected high-performance Co barrier layer, the research team successfully constructed an all-Mg-based thermoelectric module with a high filling factor. Under operating conditions of Th = 572 K and Tc = 285 K, the thermoelectric module achieved a maximum conversion efficiency of 10.2%, significantly surpassing existing nearroom-temperature thermoelectric devices (Fig. 5a,b). After stringent testing involving 600 thermal cycles (cumulatively 1,440 hours), the device performance remained stable, and the interfacial properties showed no significant changes, fully validating the superiority of the atomic-scale interface design for long-term service (Fig. 5c,d,e).

Fig. 4 (a-d) Interfacial shear strength and bonding energy calculation of the MgAgSb/Co junction. (e,f) Photographs of MgAgSb/Co junctions cut into squares with cross sectional dimensions.

Fig. 5 (a, b)Thermoelectric properties of the materials and power generation efficiency of the device. (c)Thermal cycling reliability assessment of the thermoelectric device. (d, e)Characterization of the hot-side interface of the device after cycling.

This study proposes an innovative atomic-scale interface strengthening strategy and successfully develops efficient and stable all-Mg-based thermoelectric devices with the use of high-throughput screening technology. This breakthrough achievement not only advances the development of Mg-based thermoelectric materials and devices but also holds significant scientific importance and application value for the progress of clean energy technology, laying a foundation for the future industrialization and commercialization of thermoelectric devices.