Solar-driven seawater desalination represents a green and sustainable approach to addressing global freshwater scarcity, yet with efficient and stable water evaporation remaining a key challenge. Recently, a research team from the State Key Laboratory of Advanced Fiber Materials and the College of Materials Science and Engineering at Donghua University has developed an innovative biomimetic photothermal fabric featuring a hierarchical three-layer architecture. The design incorporates two carbon-nanotube-hydrogel-coated polyester (PET) fabrics separated by fiber pillars, enabling simultaneous water evaporation from four distinct planes in a manner analogous to leaf transpiration. This structure facilitates continuous brine drainage from the bottom layer, effectively mitigating salt accumulation while maintaining high evaporation rates. The study provides new insights into the scalable fabrication of flexible two-dimensional photothermal membranes and represents a significant advance toward the industrial implementation of solar desalination technologies.

The research, entitled “Biomimetic Design of Breathable 2D Photothermal Fabric with Three-Layered Structure for Efficient Four-Plane Evaporation of Seawater,” has been published in Advanced Materials. The first author is Hu Jinjing, a Ph.D. student at the State Key Laboratory of Advanced Fiber Materials and the College of Materials Science and Engineering at Donghua University. The corresponding author is Professor Chen Zhigang, research fellow, with additional guidance and support provided by Professor Yan Wei of Tsinghua University.

(Figure 1: Schematic diagram of the research concept and technology)

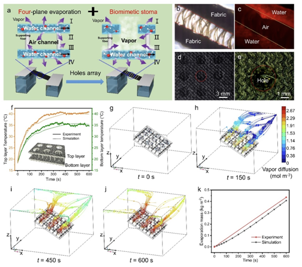

Current photothermal materials for solar desalination typically comprise 3D bulk materials and 2D membranes. While 3D architectures offer large evaporation surface areas and strong light absorption, they are often hindered by structural complexity, limited flexibility, and salt accumulation (Fig. 1a). In contrast, 2D membranes are cost-effective, lightweight and scalable but constrained by smaller evaporation areas and lower efficiency (Fig. 1b).

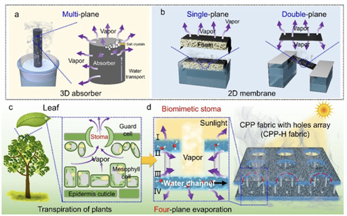

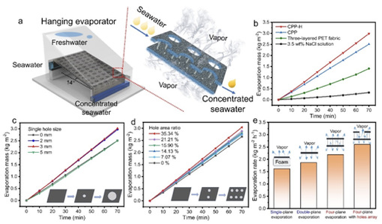

Inspired by the structure and transpiration process of plant leaves (Fig. 1c), the researchers designed a breathable 2D photothermal fabric with a three-layer configuration capable of four-plane evaporation (Fig. 1d). The top and bottom layers consist of parallel hydrophilic PET fabrics coated with carbon-nanotube/poly(vinyl alcohol)-based hydrogel (CNT/PVA), with the upper layer perforated to create a stomatal-like channel. The resulting CNT/PVA-hydrogel-coated polyester fabric with hole array (CPP-H) exhibits biomimetic leaf-like characteristics (Fig. 2a).

(Figure 2: Fabrication process and structural characterization of the three-layer photothermal textile)

The CPP-H fabric demonstrates exceptional photothermal properties, achieving 96.1% solar absorption with minimal thermal loss (Fig. 2). Surface functionalization introduces polar groups that reduce water evaporation enthalpy through hydrogen bonding and electrostatic interactions, enhancing vapor generation efficiency.

(Figure 3: Inclined evaporation device configuration and four-plane evaporation performance)

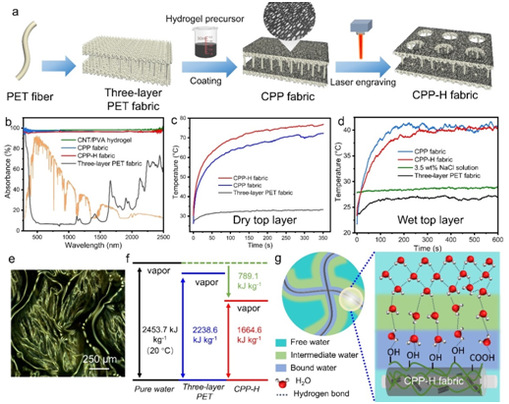

When deployed in an inclined configuration between water supply and collection tanks, the fabric enables simultaneous evaporation from four interfaces: the upper and lower surfaces of both the top and bottom layers (Planes I–IV). Vapor generated from the inner planes diffuses through the microporous upper layer, mimicking stomatal transpiration, while brine is continuously drained by gravity (Figs. 1d, 3). Under one-sun irradiation, the fabric achieves an evaporation rate of 2.6 kg m⁻² h⁻¹, significantly outperforming conventional floating evaporators (1.6 kg m⁻² h⁻¹) and hanging evaporators (1.9–2.2 kg m⁻² h⁻¹).

(Figure 4: Computational simulation of vapor diffusion through engineered pores)

Numerical simulations further validate the efficiency of this design, showing that the engineered microporous structure enhances vapor diffusion, with strong concentration gradients driving mass transfer from the inner layers to the environment (Fig. 4).

Future research will focus on optimizing material composition and micro/nanostructural features to further accelerate evaporation kinetics and reduce operational costs, thereby supporting the large-scale practical adoption of solar desalination systems.

Link to the paper: https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.202420482