Plastic reprocessing is a promising pathway toward efficient recycling and sustainable use of materials. Among various approaches, water-assisted plastic processing stands out as a low-energy, environmentally friendly technology. Previous research has demonstrated that water molecules can act as plasticizers, enabling plastics to be reshaped at room temperature. However, a persistent challenge has been the trade-off between mechanical strength and ease of reprocessing: materials that are easily reprocessable often lack robustness, while mechanically strong materials are difficult to recycle under mild conditions.

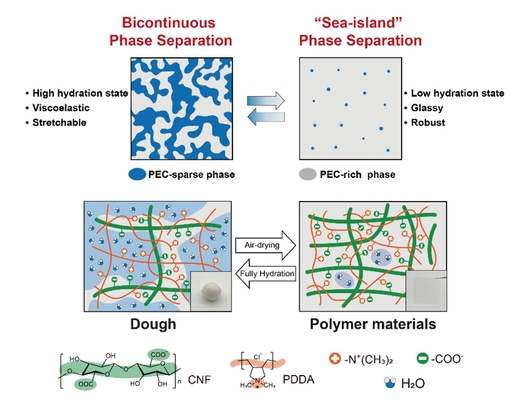

To address this limitation, a research team from Donghua University (DHU) led by Professor Wu Peiyi and Associate Researcher Hou Lei has proposed a new strategy based on water-mediated phase separation evolution. This method decouples mechanical robustness and reprocessability by leveraging different hydration states of the material. The breakthrough enables plastics that are strong and durable under normal atmospheric conditions, yet readily reprocessable at room temperature when fully hydrated.In practice, the fully hydrated material transitions into a dough-like viscoelastic state, making it easy to reshape into arbitrary forms without the need for high energy input—an eco-friendly alternative to conventional plastic processing. (Figure 1)Particularly, the plastic regains excellent mechanical performance, with tensile strength reaching 211.2 MPa and Young’s modulus up to 5.6 GPa. These values place it among the top-performing sustainable polymers capable of handling real-world, load-bearing applications.

Figure 1: Polymer material with both high mechanical properties and room-temperature reprocessability

The findings, recently published in Matter under the title “Water-mediated phase separation evolution towards mechanically robust yet room-temperature reprocessable polymer materials”, highlight a promising direction for sustainable plastic design. The work not only demonstrates the feasibility of combining strength and recyclability in one material system but also opens new avenues for energy-efficient reprocessing technologies. The paper lists Li Xiao, a master’s student at DHU’s College of Chemistry and Chemical Engineering, as the first author, with Professors Wu Peiyi and Hou Lei as corresponding authors.