Ceramics have been indispensable in human society, yet their inherent brittleness and limited deformability severely limit their applications in cutting-edge technologies. For instance, aerospace thermal insulation should withstand mechanical shocks and high-frequency vibrations, while wearable devices need to endure repeated twisting. These scenarios require ceramic components to integrate high strength, large bending strain, and even plastic deformation, which is difficult in conventional ceramic materials.

In this context, the research and development of one-dimensional ceramic nanofibers (CNFs) offers a promising pathway to overcome the brittleness of ceramic materials. Unfortunately, this desirable integration of mechanical properties in CNFs remains unrealized to date, due to challenges in precisely modulating microstructures and reducing cross-scale defects in traditional preparation methods.

Recently, Professor Ding Bin and Professor Liu Yitao from Donghua University have synthesized a linearly structured inorganic molecular chain for the first time and utilized this innovation to develop flexible and elastic ceramic nanofibers through advanced spinning techniques. This breakthrough achieves comprehensive enhancement of mechanical properties in ceramic fibers.

The landmark research, titled “Integration of high strength, flexibility, and room-temperature plasticity in ceramic nanofibers,” has been published in Nature Communications.

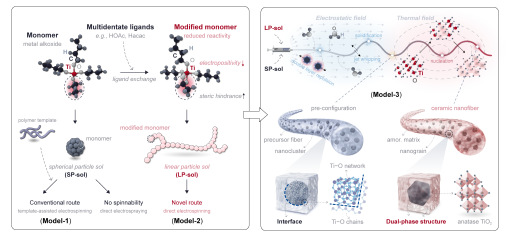

(Illustration of dual-phase structured ceramic nanofibers fabricated from linear inorganic molecular chains)

The research team developed a novel synthetic route involving coordination modification and confined hydrolysis-polycondensation of metal alkoxide monomers to produce inorganic molecular chains with linear structures. Using the titanium system as an example, the resulting linear inorganic molecular chain sol could be directly employed in electrospinning (a “self-templating” approach).

Building on this innovation, the team proposed a formation method for crystalline/amorphous dual-phase ceramic nanofibers based on interfacial nucleation regulation. The resulting dual-phase TiO₂ nanofibers exhibit a defect-free dense morphology with uniformly dispersed nanocrystals, enabling individual ceramic fibers to simultaneously achieve high strength, exceptional flexibility, and room-temperature plasticity.

Using typically brittle TiO₂ as a model system, the uniformly dispersed nanocrystals embedded in the amorphous matrix play a critical role in structural stabilization, while the amorphous phase acts as soft boundaries to effectively dissipate external stress. Moreover, the optimized dual-phase configuration significantly mitigates cross-scale local stress concentration, leading to simultaneous enhancement of tensile strength (up to 1.06 GPa), ultimate tensile strain (8.44%), and exceptional bending flexibility (curvature radius < 0.47 μm) in TiO₂ nanofibers.

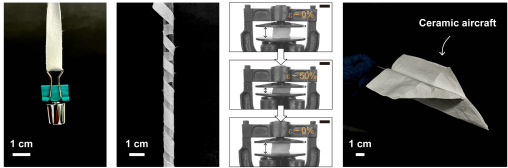

The research team further assembled these ceramic nanofibers into two-dimensional membranes and three-dimensional aerogels, which demonstrated remarkable flexibility and elasticity respectively. These findings underscore their significant potential and value for extreme applications and complex stress environments.

(Demonstration of Flexible/Elastic Properties in Ceramic Nanofibers)