The team led by Academician Zhu Meifang and Researcher Cheng Yanhua from the State Key Laboratory of Advanced Fiber Materials and the College of Materials Science and Engineering has made a breakthrough in the continuous preparation of flexible and thermally insulating aerogel fibers. Traditional aerogels, due to their inherent brittleness, poor processability, and insufficient mechanical strength, can hardly withstand the bendingand tensile stresses and washing processes in practical applications, often leading to structural collapse and a loss of thermal insulation properties. Although existing fabrication technologies (such as freeze spinning and wet spinning) enable aerogel fiber production, there are still three major challenges: ① insufficient mechanical strength; ② difficulties in the continuous production of aerogel materials; ③ significantly deteriorated spinnability of spinning solution due to the introduction of functional fillers.

To address the technical bottlenecks, the research team proposed a roll-to-roll twisted assembly strategy. This technique employs a 2D nanofiber membrane as the host layer and uses a one-step spraying-twisting process to introduce high-content (78 vol%) commercial mesoporous SiO₂ aerogel particles into the yarn matrix.

Compared with conventional methods, this approach avoids complex post-processing steps such as solvent exchange and supercritical drying, enabling continuous and efficient production of aerogel yarns. The resulting product exhibits exceptional thermal insulation properties, with a thermal conductivity of 32.3 mW·m⁻¹·K⁻¹, surpassing that of cashmere and cotton. By optimizing the twist angle to 35°, the approach results in the formation of Archimedean helices, giving the yarn improved mechanical properties: a tensile strength of 16.3 MPa and a load-bearing capacity up to 3.3×10⁴ times its own weight. Moreover, the NF-TAY (nanofiber-coated twisted aerogel yarns) demonstrates outstanding durability, maintaining robust mechanical and thermal insulation properties even under extreme temperatures (-196 to 100 °C), repeated folding and compression, and 100 washing cycles. Furthermore, the outermost nanofiberlayer extends the functionality of the NF-TAY, including hydrophobicity (with a water contact angle of 146°), dyeability, and Joule heating, making it adaptable to diverse usage scenarios and personalized needs. The findings were published in Advanced Materials under the title: “Roll-to-Roll Twisted Aerogel Yarns with Reinforced Structure and Low Thermal Conductivity.”

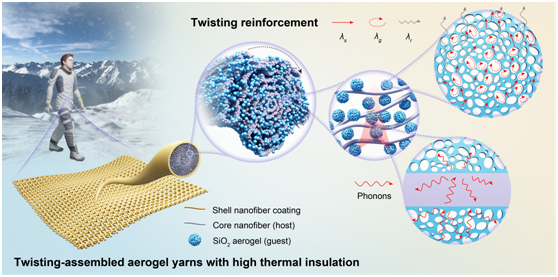

Figure 1. Fabrication of aerogel yarns and their micromorphology

Figure 1 illustrates the roll-to-roll twisted assembly processes and the morphological features of the yarn. The schematic diagram presents the three key fabrication steps: (1) Spray-coating SiO₂ aerogel/N-hexane dispersion onto a PAN nanofiber membrane; (2) Twisting to create an Archimedean yarn; (3) Encapsulation of PAN nanofibers on the outer surface of the yarn.

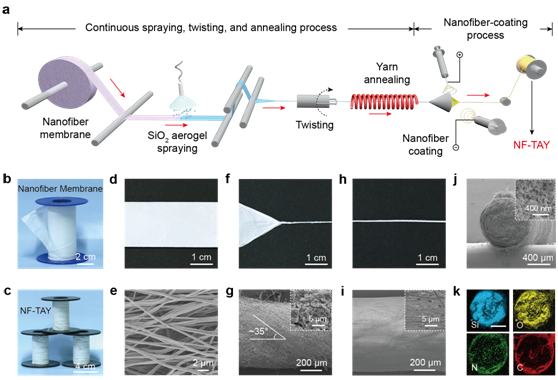

Figure 2. Mechanical properties and weavability of aerogel yarns

Figure 2 demonstrates the yarn’s strengthening mechanism and application potentials. The mechanical properties are improved from two key aspects: 1. Contribution from the highly oriented nanofiber; 2. Increased friction of the component fibers through optimization of the twist angle.

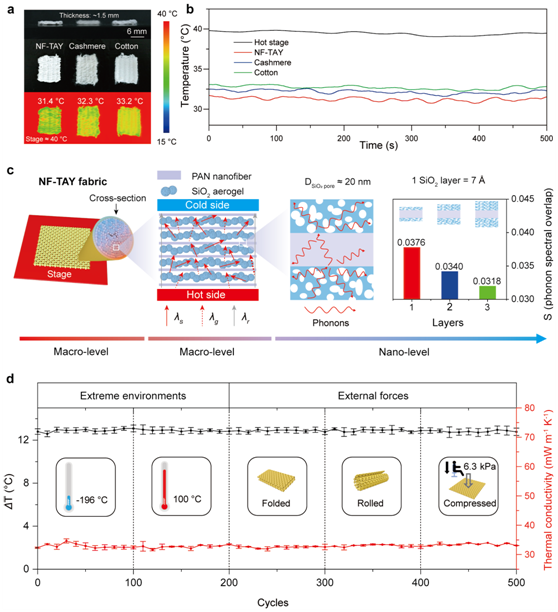

Figure 3. Thermal insulation performance and stability of aerogel yarns

Figure 3 analyzes the thermal insulation properties and multi-scale heat transfer mechanisms of the aerogel yarns. The thermal insulation mechanism primarily manifests in three aspects: 1) Knudsen effect - The pore size of the aerogel is smaller than the average free range of air molecules, weakening the capacity of air molecules to transfer heat flux within the pores; 2) Enhanced light scattering by nanofibers, reducing radiant heat transfer; 3) Phonon scattering enhancement through high porosity and weak van der Waals forces between nanofibers/aerogels, minimizing solid-state heat transfer.

Furthermore, the aerogel yarns maintain stable thermal insulation performance even after undergoing high/low temperature cycling, repeated folding and compression.

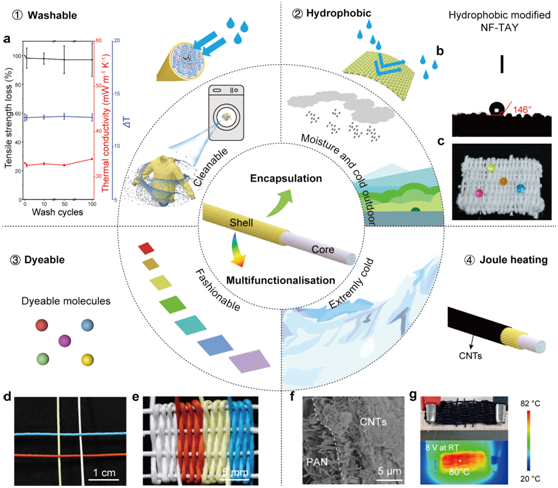

Figure 4. Multi-functionalized applications of aerogel yarns

Figure 4 demonstrates the functional extensibility and practical adaptability of the aerogel yarns. The research team validated their exceptional washing durability: after 100 washing cycles, the yarns exhibited less than 3% strength loss while maintaining nearly unchanged thermal insulation performance.