Textile is an eternal need of human beings. Based on the advantageous discipline of textile, material, and design, Shanghai-based DHU has obtained many high-level achievements. DHU developed many new fabrics and various textiles in Smart Wear, contributing to the modernization of the textile industry. Let's review some accomplishments made by DHU in the past three years.

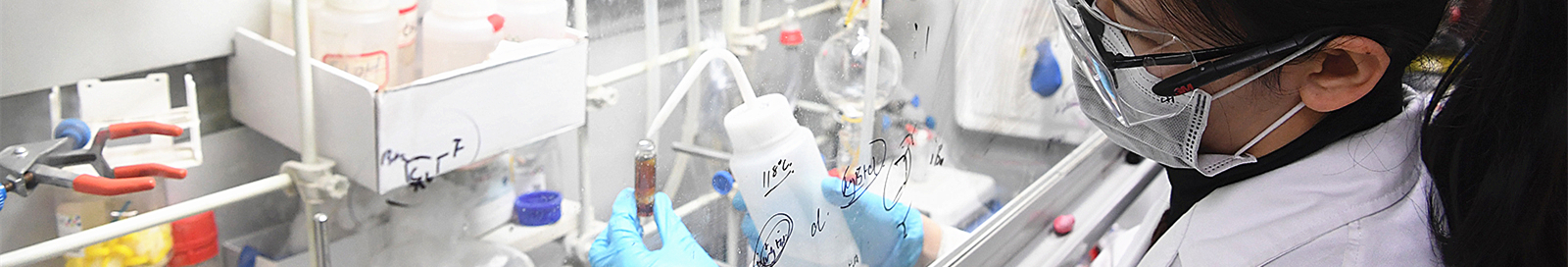

Three-layer micro and nanofiber nonwoven air filter material

---can be applied to protective facial masks.

Schematic Diagram of Structure and Design of Three-layer Nonwoven Fabric

At present, the development of a non-electret functional air filter material for the application of protective facial masks is desirable in both the academic and industrial worlds. The research team led by Zeng Yongchun at DHU has developed a three-layer micro and nanofiber nonwoven air filter material with multi-level morphology and aperture. By doping Ag nanoparticles in electrospun fibers, the filter material has successfully featured excellent antibacterial performance and achieved >99.99% antibacterial rate of Escherichia coli, which may be applied to protective facial masks.

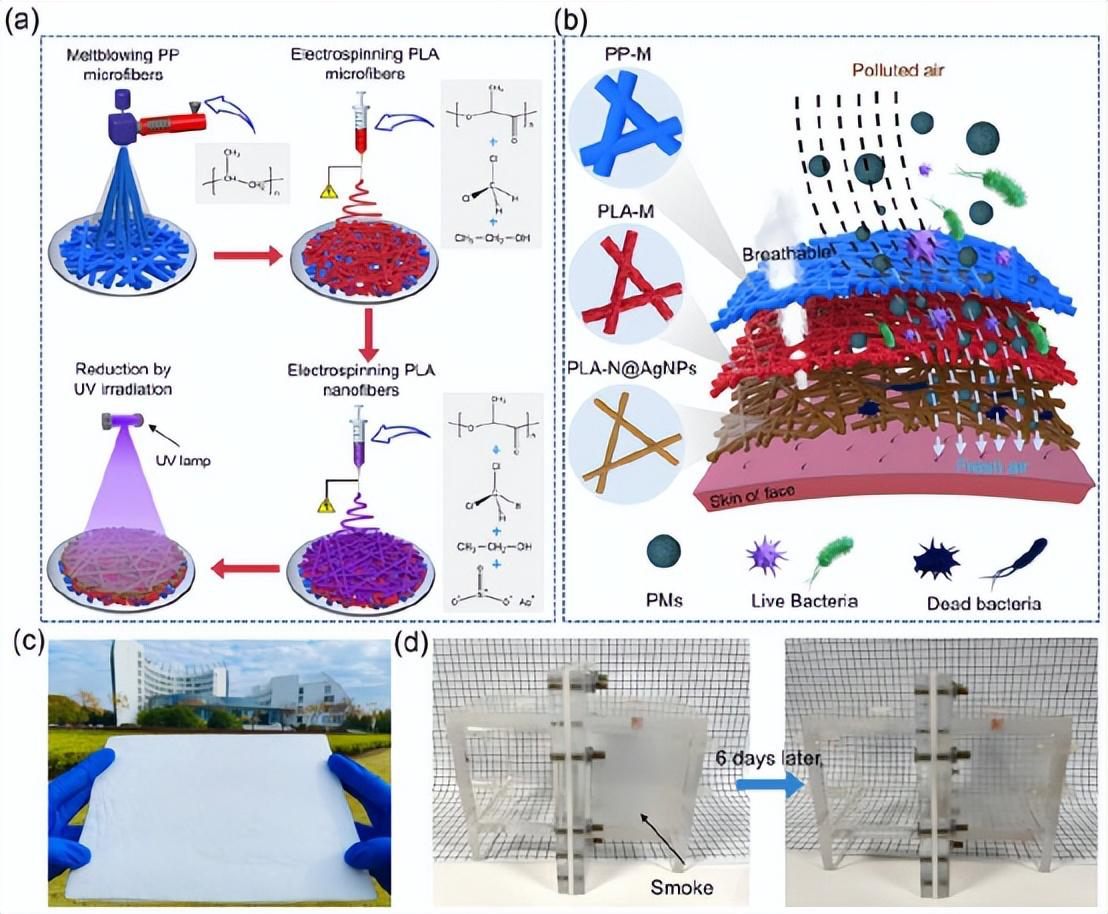

Inorganic semiconductor-based thermoelectric fabric field

--realize the solid refrigeration effect of flexible thermoelectric fabrics on the human body.

Thermoelectric Transfer Process in Thermoelectric Fabrics

The organic combination of textile structure and thermoelectric technology to develop flexible thermoelectric yarns and fabrics is one of the important research directions. The research team of S.M.A.R.T. led by Kun Zhang, a researcher in the College of Textiles, DHU, has proposed a method for developing inorganic thermoelectric block-based beaded thermoelectric yarn with high thermoelectric properties and mechanical structural stability. The thermoelectric yarn can be well woven and can be prepared in batches. The solid refrigeration effect of flexible thermoelectric fabric on the human body has been achieved for the first time.

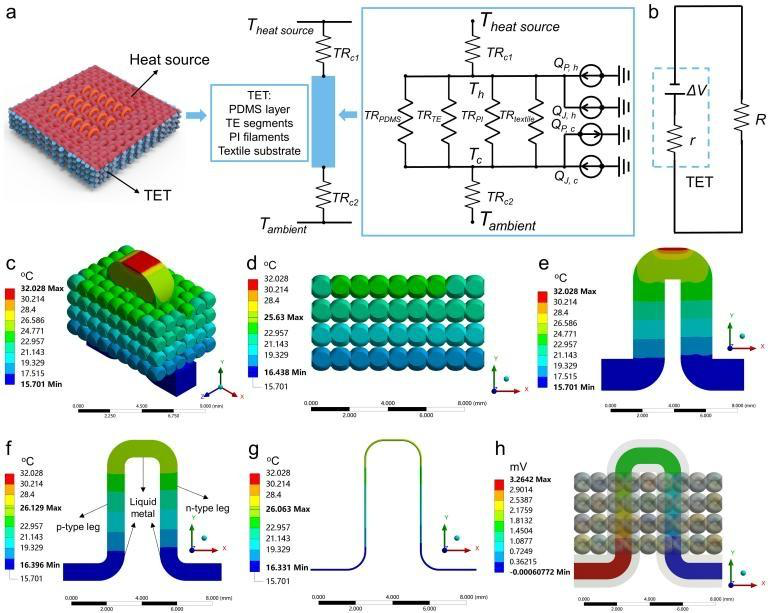

Electrospun micro and nanofiber passive radiative heating textiles field

--achieve body insulation in cold environments.

(a) Schematic Diagram of the Manufacturing Process of NanoPAN/Ag Passive Radiative Heating Textiles

(b) Personal Thermal Management Mechanism of Cotton Textiles and NanoPAN/Ag Textiles

The development of heating materials that are energy efficient and can precisely heat the human body is of great importance in alleviating the energy crisis and climate warming. The research team led by academician Yu Jianyong and Prof. Qin Xiaohong at DHU developed colored nanofiber/silver (NanoPAN/Ag) passive radiative heating textiles with adjustable color depth by electrostatic spinning-solvent impregnation-coating composite technology. The radiative heating results showed that the NanoPAN/Ag textiles could maintain the body temperature at 33-35°C under the cold ambient temperature of 14°C.

Multifunctional wearable fabric

--which can measure a series of human motion signals.

To meet the current great demands for flexible and high-sensitivity human-computer interaction materials in the wearable fabric field, a research team from DHU researched textile-based wearable sensor devices based on new nanomaterials, creatively developing the technology combining the nanomaterials (MXene, AgNWs) and yarns. The team used the results of the technology to obtain multifunctional wearable fabrics with high strain sensitivity and high electrothermal efficiency (1.8V, 50°C), which could successfully measure a series of human motion signals (walking habits, facial expressions, etc.).

New fabric with silk texture

--which can empower rural revitalization with technology.

Today, a new natural fabric with a texture as smooth, breathable, and comfortable as silk may bring progress to the textile and garment industries. It comes from a plant called calotropis gigantea. The research team led by Li Yuling, DHU, is the team that develops a new fabric with silk texture. Today, the team is undertaking the project of "demonstration of fiber lifting and health preserving of natural characteristics hollow-fiber plant in Red River Valley ", which is dedicated to solving the problem of natural hollow fiber spinning of calotropis gigantea and empowering rural development with science and technology.

New sports fabrics

--feature properties of highly effective antimicrobial, moisture-transfer, and dry-fast.

People will produce a lot of sweat and other secretions during exercise, reducing wearing comfort and brewing various bacteria, causing hygiene problems. Sports fabrics that can be antimicrobial with high efficiency and durability and release sweat to keep the microenvironment dry are essential. DHU's micro and nano fabric research group has made technical innovations to the traditional cotton spinning process, embedding functional micro and nanofibers. It overcomes the problem of cross-scale blending of micro and nanofibers and cotton fibers and develops a sports fabric with properties of high comfort, high-efficiency antibacterial, moisture-transfer, and dry-fast.

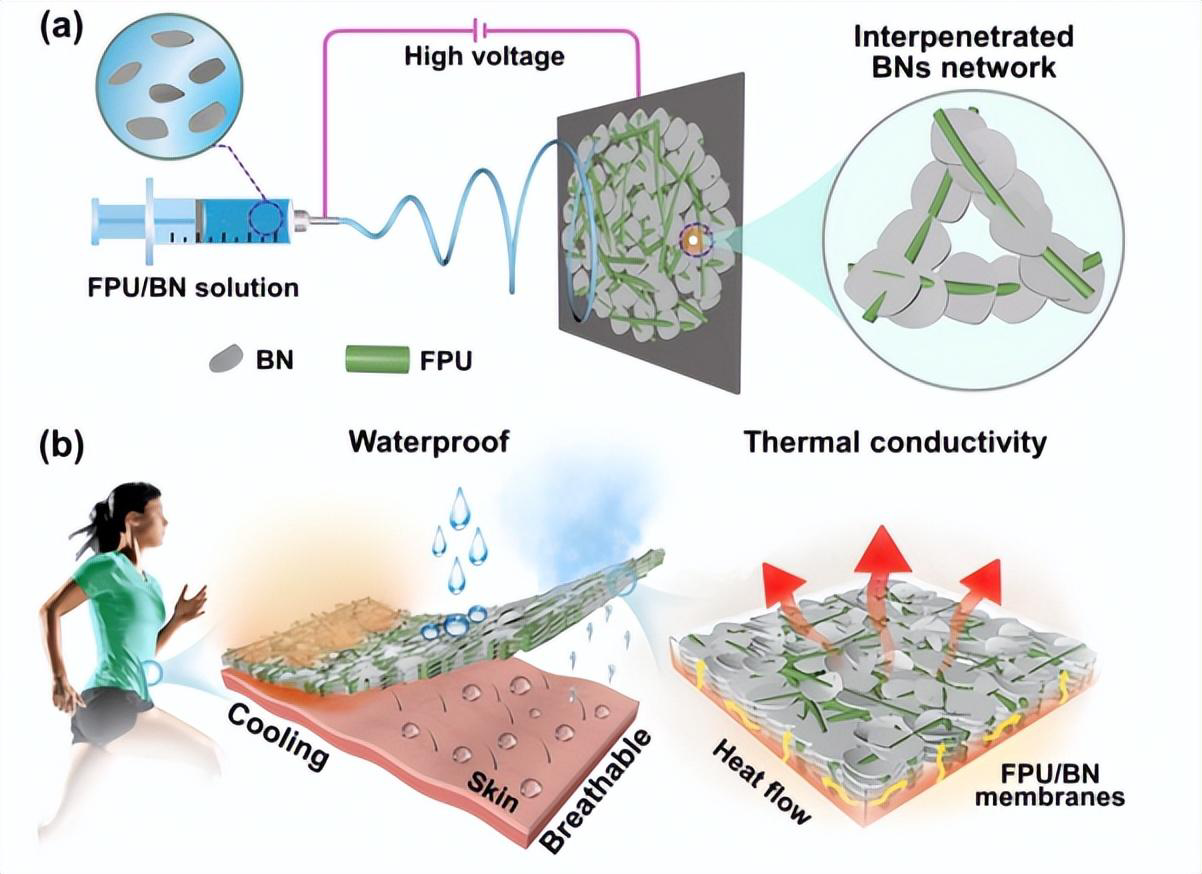

New cooling material

--which can keep wearers cool in summer.

(a)Schematic Diagram of the Preparation and Structure of the FPU/BN Membranes

(b) Schematic Diagram of the Waterproofness, Breathability, and Thermal Conductivity of FPU/BN Membranes

The research team led by Prof. Ding Bin and researcher Si Yang has designed a material, FPU-BN, which can be cooled wearers down without any electricity. FPU-BN membranes are made by an electrostatic spinning machine by mixing a polymer (polyurethane), a hydrophobic polymer (fluorinated polyurethane), and a thermally conductive filler (boron nitride nanoflakes). It can effectively dissipate heat from the wearers while being breathable, waterproof, and easy to manufacture.

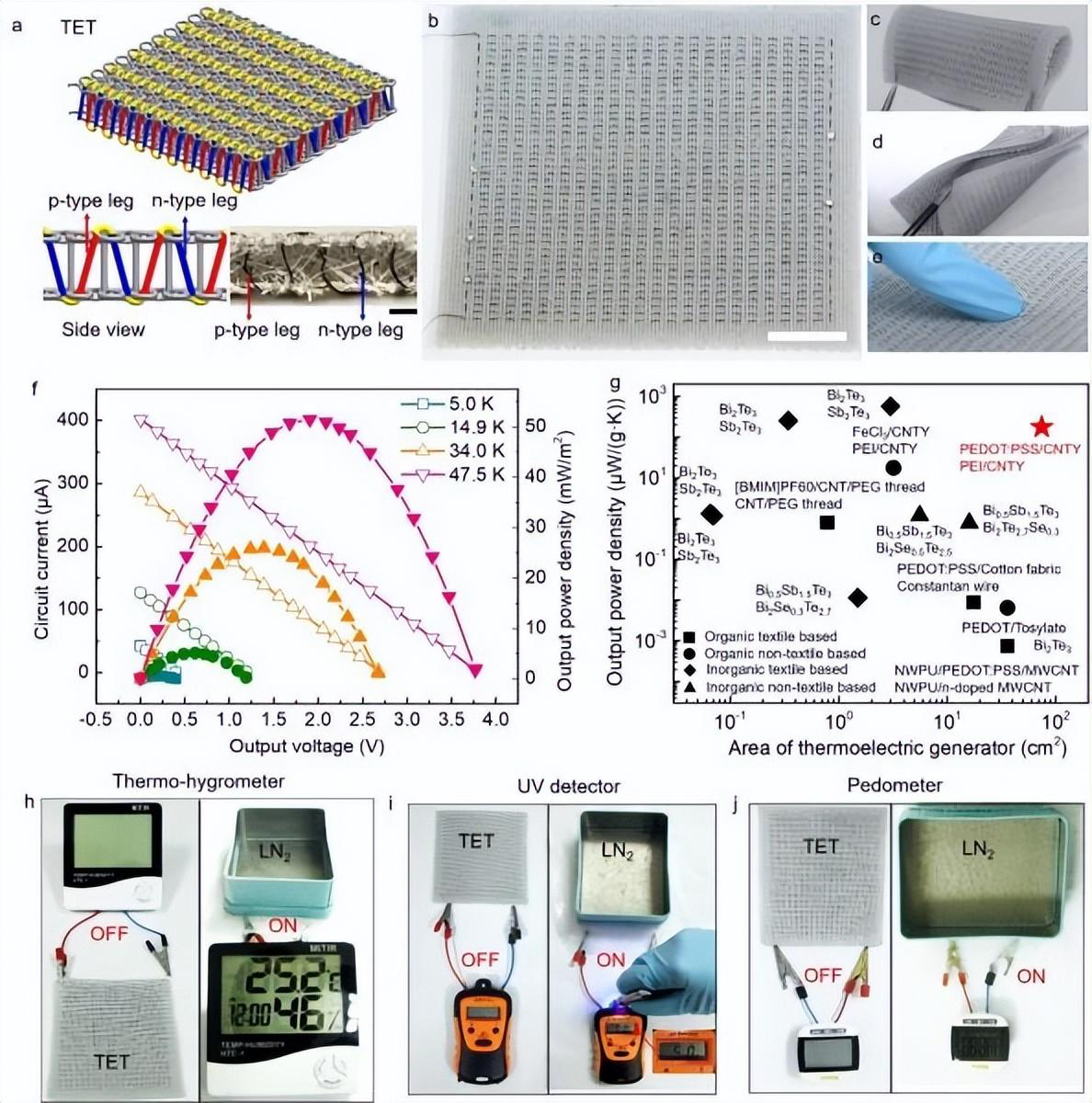

Flexible and wearable thermoelectric fabric

---can achieve autonomous power supply for wearable electronic devices.

Demonstration of Thermoelectric Fabrics and

the Thermoelectric Output Performance and Application

In the fields of the Internet of Things, extreme sports, wilderness survival, and artillery, most wearable electronic devices are vulnerable to the impact of battery capacity and power supply continuity. The research team, "Smart Wearable Textiles", led by Zhang Kun in the College of Textiles, DHU, has made progress in flexible wearable thermoelectric fabrics by combining traditional textile and thermoelectric technologies to produce thermoelectric fabric. The fabric can supply power autonomously to wearable electronic devices by the temperature difference between the human body and the environment while being comfortable to wear.