Tooth enamel is a hard tissue with high calcification. It has a tightly ordered arrangement structure of hydroxyapatite (HAp) nanocrystals to satisfy its mechanical strength and toughness. At present, the unique structure of natural enamel can be bionic by bio-mineralization and inorganic substrate synthesis. However, the above methods can only achieve the ordered arrangement of a single horizontal HAp at the nanoscale, micron scale, or in a rough macroscopic shape. And the natural enamel has not only the outer structure arranged in parallel, but also the inner structure with certain deflection angle. More importantly, its clear macroscopic structure (thickness greater than 1 cm and size greater than 1 cm) further increases the difficulty of preparing bionic enamel. At present, the printing accuracy and effect of 3D-printed teeth are increasing from the initial stage of simple materials printing tooth model to the stage of optimal performance printing,andthen to the stage of further mixing active cells, antimicrobial materials, andgrowth factors etc. Nevertheless, the performance of natural teeth is not repeated, and it still needs more efforts for clinical application.

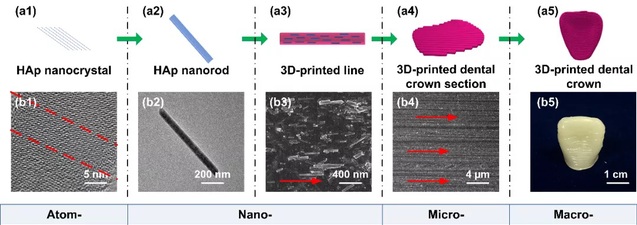

Figure 1. 3D Printed Strong Dental Crown with Multi-Scale Ordered Architecture and High-Precision

Inspired by the multi-stage growth of enamel in natural teeth, Professor Zhang Yaopeng and Zhu Meifang, academicianof the State Key Laboratory for Modification of Chemical Fibers and Polymer Materials of Donghua University, developed a bottom-up step-up assembly strategy based on a single dispersed "supergravity +" HAP-based dental repair resin materials and extruded 3D printing technology. The team used shear induction to construct a high-precision bionic crown of multi-scale highly ordered HAp structure, realizing the composition (HAp), structure (tightly ordered) and properties (mechanics and rematerialization) of natural teeth. The results were published in Advanced Science under the title “3D Printed Strong Dental Crown with Multi-Scale Ordered Architecture, High-Precision, and Bioactivity”, with PhD student Zhao Monroe as the first author, Dr. Fan Suna, associate Prof. Yao Sung, and PhD student Dr. Daniel Yang at Beijing Chemical University co-authors. Prof. Zhao Yaopeng and academician Zhu Meifang are co-corresponding authors. Part of the experiments were completed in BL19U2 beamlineat the Shanghai Synchrotron Radiation Facility (SSRF), and the "supergravity +" hydroxyapatite was prepared in cooperation with Beijing University of Chemical Technology.

8

Figure 2. 3D Printing Process Schematic Diagram Based on Highly Ordered HAP Composite Resin Crown

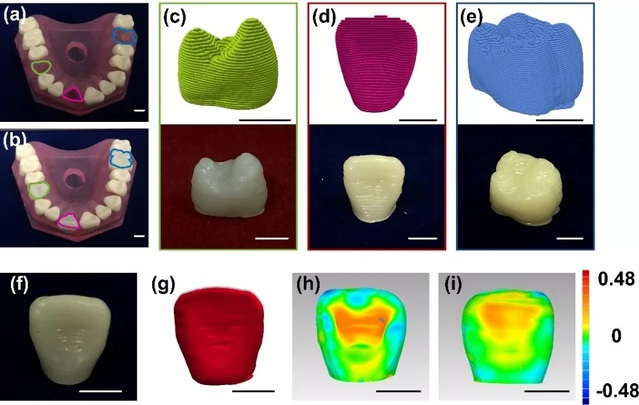

Figure 3. Personalized Repair of 3D Printed Crown

A single dispersed "supergravity +" HAP-based tooth repair resin materials were prepared, so that the HAp nanorod dispersed evenly and steadily in the resin matrix. According to the rheological behavior of different formulations, the best print ink formula for shear induction was selected by theoretical calculation. Based on the rheological properties of the slurry, a custom-made nozzle with progressive shrinkage channel was designed by calculating the fluid dynamics to facilitate smooth extrusion and stable shearing of the slurry (Fig. 1).

Based on the nanocrystal structure of HAp (atomic scale), the single dispersed nano-rod was orderly arranged along the printing direction (nanoscale) affected by shear induction in the printing process, for the purpose of making the printing path in parallel (micron scale). Thus, a 3-D highly ordered resin sample prepared on a macro level could be used for printing personalised-restoredcrown (Fig. 2), according to the3-D model of the crown.

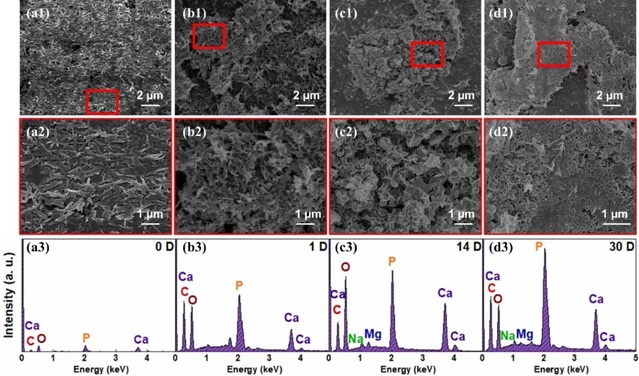

Its printing accuracy could reach to95% (Fig. 3). Due to the expansion of cracks stopped, the orientation degree of a nozzle with a minimum diameter of 260μm is the highest while printing, of which bending strength could be up to 138 MPa, and of which compression strength 370 MPa, with better result than the sample prepared by traditional mold (Fig. 4). Its superiorremanufacturing activities reduced the speed of bacterial aggregation and the secondary caries (Fig. 5) . This work result made the preparation for unique structures and functions of bionic materials more possible.

Figure 4. Mechanical Properties and Cross-Sectional Topography of HAp Composite

Resin

Figure 5. Bioactivity of HAp Composite Resin in Vitro

This project is sponsored by the National Key Research and Development Plan (2016YFA0201702) and Shanghai Municipal Outstanding Academic Leaders Plan(20XD1400100. Special thanks to Ning Mianbo, an engineer from Shimadzu Manufacturing Company for his assistance and support in Micro-CT testing.

In recent years, Professor Zhang Yaopeng's team has achieved a series of research results in the research direction of 3D printed biomimetic materials(Compos. Sci. Technol., 2021, 213, 108902; Cellulose, 2021, 28, 241-257; Carbohyd. Polym., 2019, 221, 146).