The success or failure of minimally invasive surgery for the treatment of coronary heart disease, cerebral apoplexy, aortic aneurysm, atrial fibrillation or other diseases (Figure 1) and the comfort of patients are closely related to the hollow fiber catheter. Catheters that are too soft are unable to smoothly pass through the blood vessel to reach the lesion location, which my lead to surgical failure; Catheters that are too hard may make patients’ uncomfortable and are likely to puncture the inner walls of the blood vessels, resulting in surgical accidents. As an advanced fiber material, the preparation technology of hollow fiber catheters for minimally-invasive interventional treatment has been blocked by foreign companies for a long time, leading to the formation of a monopoly market, which has the risk of “blocking the neck”. The clinical use of the material relies heavily on imports, causing huge costs.

Figure 1 a)coronary heart disease,(b)cerebral apoplexy,(c)aortic aneurysm,(d)atrial fibrillation

Professor Yu Muhuo of the College of Materials Science and Engineering of DHU paid attention to the technical problems of this catheter material more than ten years ago. He was determined to break the blockade, led the team to carry out a long-term research on hollow fiber catheter technology through industry-university-research cooperation with the hollow fiber catheter technology center of Shanghai MicroPort Medical (Group) Co., Ltd. (hereinafter referred to as “MicroPort Group”) , and made a series of important progress. Recently, the project “Key Technologies and Industrialization of Preparation and Composite Reinforcement of Hollow Fiber Catheters for Minimally-invasive Interventional Treatment” presided over by Professor Yu Muhuo won the first prize of Shanghai Science and Technology Progress Award.

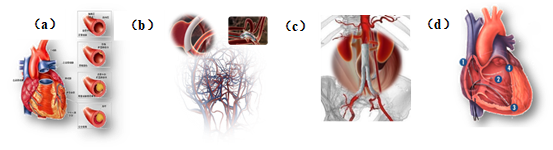

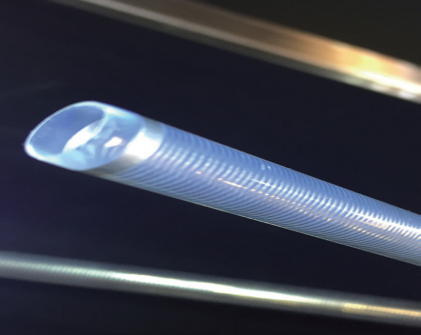

According to information, the current global market for minimally-invasive interventional medical devices is valued at US $400 billion. Hollow fiber catheters are the key components for this kind of medical devices, including single cavity, multi-layer, multi cavity, balloon, braided composite reinforcement, and coil composite reinforcement (as shown in Figure 2), accounting for 60-80% of the cost of device materials. Clinically, the requirements for penetration, tracking, torsion control, and pressure resistance of such catheters are very high, so their manufacturing is facing great difficulties.

Single cavity and multi cavity Multi-layer

Braided composite reinforcement Coil composite reinforcement Balloon

Figure 2 Hollow Fiber Catheters for Minimally-invasive Interventional Treatment

Professor Yu Muhuo led the team to give full play to the technical advantages of DHU in spinning and systematically study the influence of spinneret components and melt flow shear expansion extension and other factors on the dimensional accuracy, strength and toughness and biocompatibility of hollow fiber catheters, realizing the synchronous improvement of axial and radial strength, toughness and rigidity of the catheters.

Figure 3 Professor Yu Muhuo giving an academic report

In terms of the requirements of excellent torque control performance for electrophysiological radiofrequency ablation catheters, electrophysiological mapping catheters, angiographic catheters and guiding catheters, Yu Muhuo and his team enhanced the interface strength of hollow fiber catheter through the design of metal wire interface and grid structure, realized the precision control of high rigid metal wire mesh, and effectively improved the torque control performance of the catheter.

Balloon products are a big part of coronary intervention therapy, putting much more requirements on their high blasting pressure-tolerant strength. By inflating the balloon, the plaque on the inner wall of the blood vessel can be torn and broken, leading the blood to flow smoothly, and by expanding the stent, it can be fixed on the inner wall of the blood vessel, thereby forming a channel through which the blood can flow. The shell-like hollow fiber balloon with multistage structure developed by the team has enhanced the fracture toughness of the balloon, realized the performance requirements of thin-wall thickness and high blasting pressure-tolerant strength of the balloon, and improved the safety of clinical operation.

After over ten years of research and development, the team has resolved the key technical problems of the manufacturing, dimensional accuracy, composite reinforcement, balloon toughness, nested welding of hollow fiber catheter. It has developed more than 200 kinds of hollow fiber catheters, established 30 production lines (as shown in Figure 3), taken the lead in realizing localization, produced more than 30 million catheters in total, provided support for the R & D and production of more than 200 kinds of minimally-invasive interventional medical devices in 30 series of MicroPort Group and its subsidiaries, and established a special database with its main technologies and products reaching the international leading level. Currently, hollow fiber catheters are gradually sold to other domestic companies for product development and production, critically contributing to the great-leap-forward development of high-end medical devices, the improvement of their competitiveness and the advancement of technology in China.

Figure 4 Production line of hollow fiber catheter

Professor Yu Muhuo, born in the 1960s, highly praised the team composed of members born in the 1980s. This is a high-level and professional “Warriors” team, who dare to make breakthroughs. Cherishing a hope of creating native hollow fiber for minimally-invasive interventional treatment, each team member has been focused on tackling key technological problems of the hollow fiber catheter for more than ten years. Li Zhaomin, after graduating from Professor Yu’s group with a master’s degree, joined MicroPort Group, is responsible for the technological matters related to hollow fiber catheter. He went back to school many times to ask Professor Yu about the R & D of hollow fiber catheter. Technical problems from the front line of production quickly became the key research topics for Professor Yu’s laboratory. A few years later, Li Zhaomin returned to DHU to study for a doctoral degree, with Professor Yu as his supervisor. Currently, he is a postdoctoral fellow jointly trained by MicroPort Group and DHU, and continues to study related topics of hollow fiber catheters under the guidance of Professor Yu.

Figure 5 Professor Yu Muhuo and his students

Figure 6 Group photo of the teachers and students from Professor Yu Muhuo's team

The value of the cognition and practice of science has been fully reflected in this project. Professor Yu Muhuo also told the reporter, “There is a workshop in the company where almost all the employees graduated from DHU.” This is one of the proudest things for a scientist and educator.