Conjoined protective clothing of limited use, nonwoven materials for the production of anti-epidemic goods and materials, making digital "ID card" for colors and so on. The 22nd China International Industry Fair opened in Shanghai, and 11 scientific and technological achievements of Donghua University exhibited in the fair. These projects served the national economy and the people’s livelihood, boosted industrial development, and had broad application prospects. Since the outbreak of COVID-19, Donghua University had accelerated in scientific research to make key technological breakthroughs.

Urgent! Hard! Make what is badly needed and not available in China

On January 28, the fourth day of Chinese New Year, on the way back to Shanghai from her hometown Nantong, Zhu Meifang, Academician of the Chinese Academy of Sciences and Director of the State Key Laboratory for Modification of Chemical Fibers and Polymer Materials (Donghua University), scanned the news about the epidemic: masks and protective clothing were in short supply; medical staff were at risk of infection… The news kept Mrs. Zhu in suspense, and she urgently held an online meeting, issuing the notice and guide on emergency application for medical and protective materials against COVID-19. “Make what is badly needed and is not available in China.” Zhu Meifang’s team immediately launched the research and development of “conjoined protective clothing of limited use made from Rowelk®, the new wear-resistant and breathable material of high-quality barrier of Dangsheng” by cooperating with Dangsheng Company founded by alumni Luo Zhangsheng, striving to produce high-quality protective clothing of limited use and send them to the anti-epidemic front line as soon as possible.

Under the circumstances of the shortage of workers and raw materials, the scientific research team and the head of Dangsheng Company worked hard to “race against the clock to tackle key problems in scientific research” and “go back to the front line to be a worker again”. After three or four days, they succeeded in delivering the sample. Dangsheng Company also submitted a letter of application for battle assignmentsto the local government, which immediately received support. With the joint efforts of the project team, the production of the conjoined protective clothing of limited use started immediately. They overcame thetechnology bottleneck of instantaneous pressure relief and spinning forming, and delivered safe protection materials of high-quality barrier, high wear-resistance, and high moisture permeability, the tear resistance of which was 2-3 times higher than ordinary protective clothing fabrics. The team successfully developed high-quality conjoined protective clothing of limited use with good protection, comfort and long-lasting durability, which could be reused after irradiation and sterilization with cobalt 60,some physical and chemical indexes of which even exceeded the similar products of DuPont Company. The production capacity reached about 2000 pieces per day in a short time. The project was also selected into the High-end Epidemic Prevention Products Projecturgently launched by National Natural Science Foundation of China.

(Rowelk® conjoined protective clothing of limited use)

At the beginning of this year, the project team successively donated more than 5000 sets of Rowelk® conjoined protective clothing of limited useto Wuhan Mobile Cabin Hospital, the People’s Hospital of Hanchuan, National Research Institute for Communicable Disease of China Center for Disease Control and Prevention, Shanghai Medical College of Fudan University and other units at the anti-epidemic front line, as well as cooperative units such as Advanced Energy Technology Center in New York State and Dresden University of Technology in Germany, which easedthe dilemma of protective clothing shortage, and enhanced the anti-epidemic strength of international cooperation units.

Scientific research to tackle key problems to ensure the production of anti-epidemic materials

During the COVID-19 epidemic, nonwoven medical protective products such as masks, protective clothing, isolating clothing and surgical clothing became the key anti-epidemic tools. The quality and function of nonwovens were the key to the effective protection from bacteria and viruses. We could not afford any mistake in every detail of the R & D and production stage. In the front line, doctors and nurses were fighting the virus at close quarters; in the rear, how couldwe do a good job in daily protection to build a safe “protective wall” for medical staff and ordinary people? Professor Jin Xiangyu’s team of College of Textiles focused on key technological breakthroughs on the characteristics and application technology of the key anti-virusmaterial of masks —spun-melt nonwovens.

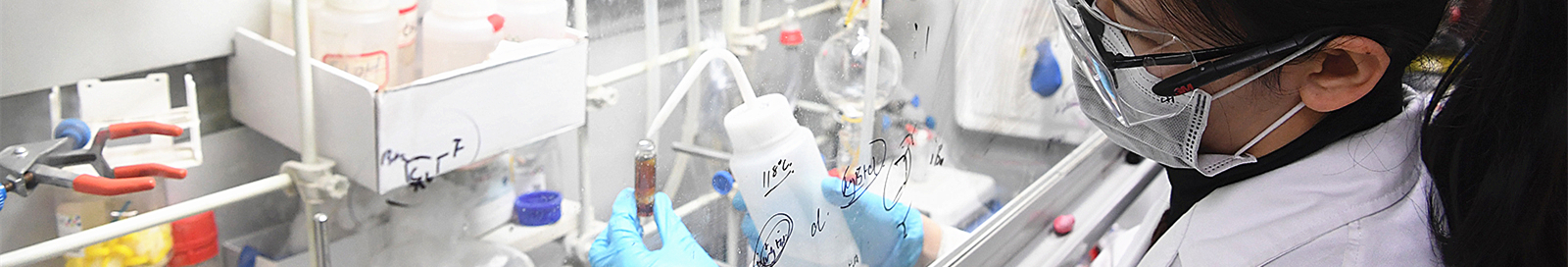

(Jin Xiangyu’s team during the epidemic)

In view of the problems of low filtration efficiency and difficulty in the balance of filtration efficiency and filtration resistance of spun-melt nonwovens, Jin Xiangyu led the team to set up a “scientific research military pledge” to carry out the research and development of “high-quality spun-melt nonwoven filtration materials and long-term electret technology”. They developed gradient filtration structure, improving the material bulkiness and fiber diameter uniformity, reducing the filtration resistance and improving the dust holding capacity of the material, to improve the air permeability of masks.In regards to the melt blowing process, they developed special long-term electret organic masterbatch. Through electret technology, nonwovens were charged with static electricity, and more finer particles would be filtered. The filtration efficiency of related products is more than or equal to 95%. Compared with ordinary masks, it not only improved in air permeability and comfort of wearing, but also realized efficient protection. The team also developed a high-voltage long-distance pointed-end corona discharge electret equipment, using the external corona charging method to do electret treatment for spun-melt nonwovens.

At the present, the spun-melt nonwoven technology has been widely applied throughout the country, and through the cooperation with domestic leading enterprises of spun-melt nonwovens, the achievements have been transformed, and more than ten demonstration production lines have been built. The spun-melt nonwovens produced have been used in medical masks, non-medical masks, children masks, protective clothing and isolation clothing, etc., effectively guaranteeingthe production of anti-epidemic materials.

Jin Xiangyu was recently awarded “National Advanced Individual in Textile Industry in the Prevention and Control of COVID-19 Epidemic”. He led the team to devote to the development and application of medical protective nonwovens for a long time. Since the 2003 SARS period, the team had continuously developed protective mask filters, medical protective clothing materials and other achievements, all of which had reached the international leading technology level.

Let colors have their own globally accessible digital ID card

China red, Tiffany blue, Starbucks green... These well-known colors have become the brand awareness of consumers. In the textile design and production, it is one of the biggest global problems of how to realize the efficient and accurate control of fabric color and digital transmission and communication. As a large textile country, China has an annual output of more than 100 billion meters of textile fabrics. However, the expression of color in fabric development of enterprises mostly depends on the “experience” of master craftsmen. It takes a long time to match color manually and matching and make physical samples, and there is a lack of scientific control of color.

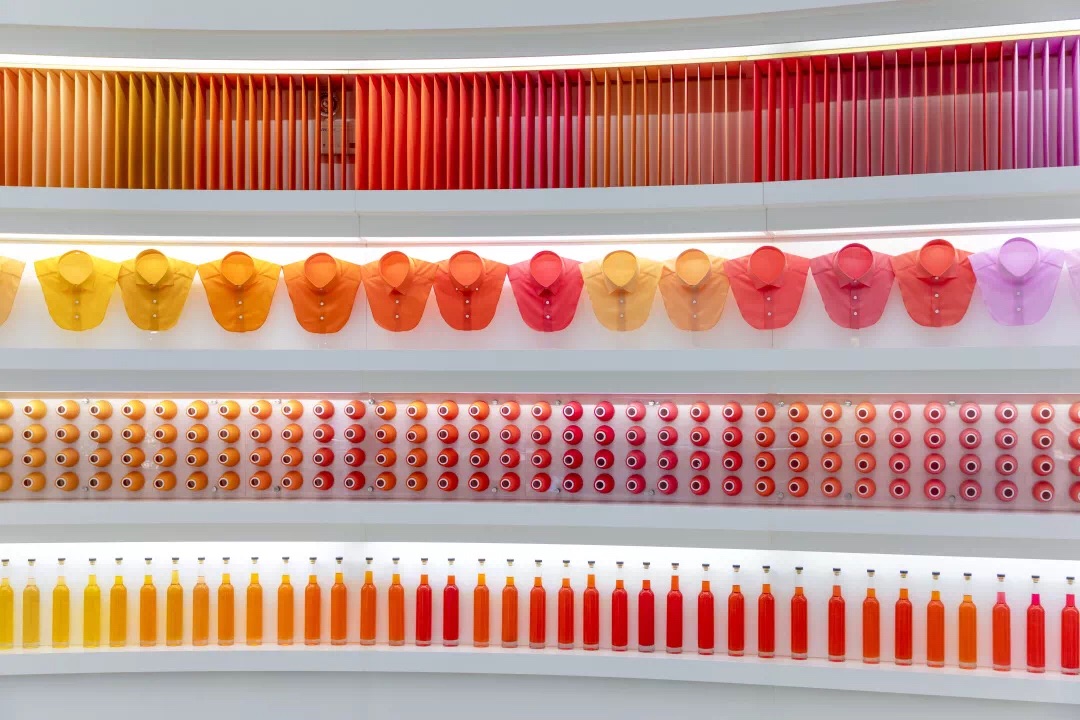

(Partial samples of in the fabric museum of the cooperative enterprise)

In the face of this common problem in textile enterprises, Professor Zhang Ruiyun’s team of College of Textiles startedtheir scientific research in the fields of color matching of colored spun yarn, fabric simulation and fabric database. Since 2012, the team have independently developed the reflectance spectrum system and high coverage gamut system of full spectrum dyes and colored fibers, created the spectral matching model of mixed color and monochrome, and ensured the high matching between mixed color samples and monochromatic fabrics.They have developed virtual simulation and image database of fabrics and realized intelligent retrieval. The project of“the Color Digital System of Colored Spun Yarn and Yarn-dyed Fabric” realizes the rapid color matching and predictionof colored spun yarn, and optimizes various color mixing schemes and suitable color matching models of colored fiber.The accuracy rate of one-time color matching reaches more than 85%, which greatly improves the color matching efficiency of colored spun yarn.The intelligent retrieval system of large volume of yarn-dyed fabric library adopts 3 kinds of algorithms to fast track the fabric. The minimum time consumption of single image retrieval among 10 thousand samples is about 3 seconds, and the highest accuracy rate is 95%.The project has applied for 4 invention patents, and has gained 2 authorized ones. The project of “Key Technology and Industrialization of Textile Fabric Color Digitization”, which contains part of the above-mentioned technical content, has won the second prize of StateScience and Technology Progress Awards in 2019.

Professor Zhang Ruiyun believes that the breakthrough in the key technology of color digitization of textile fabric is not only the technological innovation in the textile field, but also the innovation “blessing” in various fields such as textile dyeing and finishing, textile design, computer graphics and image processing and cloud platform technology. The successful development and smooth implementation of the project technology benefit from the efforts of the research team, as well as the accumulation of DHU in the field of textile discipline and the help from the “comrades” of various collegesfor their cross-border cooperation. The cooperativeenterprises and the cooperative colleges are all on the same boat. Only by working together to overcome the difficulties and make concerted efforts, can this technology be truly implemented and industrialized.

The participated projects of DHU also included“New Intelligent and Functional Polyurethane Materials” by Professor You Zhengwei’s team of College of Materials, “CHES-FY Handle Style Tester of Textile Materials” by Professor Du Zhaoqun’s team of College of Textiles,“Development of New Green and Efficient Titanium Nano Catalyst and Its Application and Promotion in Polyester Industry” by Professor Sun Bin’s team of College of Materials, “High Performance Liquid Crystal Polyarylate Fiber” by Associate Professor Wang Yanping’s team of College of Materials, “Key Technologies for Complete Set of Indoor VOCs Purification Equipment in Industrial Places” by Associate Professor Liu Baojiang’s team of College of Chemical Engineering and Bioengineering, “Ecological Fiber Made From Silicon and Nitrogen Flame Retardant Cellulose and Its Fabric Products” by Associate Professor Chen Ye’s team of College of Materials, “Aviation-grade Thermoplastic Composites” by Associate Professor Zhu Shu’s team of Center for Civil Aviation Composites, and “Ankle Protector for Ankleswith Varus Violence” by Associate Professor Guan Guoping’s team of College of Textiles. The high-quality scientific and technological achievements demonstrate intelligence, environmental protection and quality life.

At the invitation of Shanghai Municipal Commission of Economy and Information, the State Key Laboratory for Modification of Chemical Fibers and Polymer Materials (Donghua University) and College of Material Science and Engineering organized the teams to participate in the new material industry exhibition with the theme of “Next Generation Fiber Makes LifeBetter”, including high-performance fiber and composite materials, functional fiber and low-dimensional materials, environment-friendly and biological fiber materials,medical and health protection materials, etc.

Taking part in China International Industry Fair in successive years has become a vivid miniature of Donghua University’s exploration and integration with industrial development and our efforts in enabling the industry with science and technology. We have successively won the special prize,the excellent organization award and the advanced individualof the project of university exhibition area. In recent years, DHU has focused on the major needs of the country and the industry, based on the Yangtze River Delta and radiated the whole country.Focusing on building a collaborative innovation system, we transform the scientific research achievements into the “combat strength” of the industry, the “vitality” of the industry, and the “power” of enterprises, providing services to support scientific and technological innovation of textile, materials, medical treatment, clothing, design and other industries, and accurately connecting scientific and technological achievements and industrial production practice. Efforts have been made to use the optimal Donghua solution to break through the bottlenecktechnology, forming significant landmark achievements, which have been widely used in aerospace, defense force, major construction projects, environmental protection, medical and health care, fashion design and other fields, producing remarkable economic and social benefits, and enabling the development of the industry with intelligence and interconnection.