The 21st China International Industry Fair (CIIF) was unveiled on September 17 in Shanghai. Eleven scientific and technological achievements of Donghua University (DHU) were shown at the fair. They are “Weaving Technology and Equipment of High-Performance Special Woven Fabrics” from the team lead by Professor Sun Yize of the College of Mechanical Engineering, “Industrialization of Efficient Recycling of Waste Polyester and Fiber Preparation” from the team led by Wang Huaping, Deputy Dean of the Research Institute and researcher of the College of Materials Science & Engineering, “Development of Composite Materials for Rail Transit” from the team led by Professor Wei Yi of the Center for Civil Aviation Composites, “Synthesis of Durable All-Cotton Easy-To-Wash Finishing Agent and Its Application in Home Textiles” from the team led by Associate Professor Min Jie from the College of Chemistry, Chemical Engineering & Biotechnology, “Sonic Fire Extinguisher” from the team led by Associate Professor Guan Hongyun of the School of Information Sciences & Technology, “High-strength PP Fiber Self-Reinforcing Composite Luggage” from the team led by Associate Professor Pan Lijian of the Center for Civil Aviation Composites, “Nano-Manganese Non-Photocatalytic Aldehyde Removal Material” and “Flexible Ceramic Nanofiber Material/“Ultra-light, Super-elastic Ceramic Nano-Fiber Aerogel High-Temperature and Heat-Insulating Materials” from the team led by researcher Ding Bin of the Innovation Center for Textile Science and Technology, “Zero Discharge of Printing and Dyeing Wastewater” from the team led by Associate Professor Ma Chunyan of the School of Environmental Science and Engineering, “A High-Quality Sewage Treatment System for Water Discharge, Energy Recovery and Resources Recycling” from the team led by Associate Professor Yang Bo of the School of Environmental Science and Engineering, and “High Performance Liquid Crystal Polyarylate Fiber” from the team led by Associate Researcher Wang Yanping of the College of Materials Science & Engineering.

(DHU booth at CIIF)

Create a “special force” of textile machinery

Jiaolong is China’s first deep-sea manned submersible. The rope tied between Jiaolong and its mother ship is called umbilical cable. Since it plays a major role in power supply, signal transmission and hydraulic passage when Jiaolong operates in the deep sea, it is therefore the “lifeline” for the operation of underwater equipment. However, it is of great difficulty to develop and produce such a device,and Professor Sun Yize’s team solved the problem.

Since 2009, Sun Yize has led the team to cooperate with leading companies for continuous scientific research on weaving technology and equipment of high-performance special woven fabrics, aiming to create a “special force” for textile machinery. So far, the team has not only developed the results of a completely independent intellectual property system, but has been authorized with 45 invention patents, presided over the formulation of 4 industry standards, participated in the formulation of 5 national standards, and achieved a large-scale industrialization-the special weaving equipment developed through university-enterprise cooperation accounts for more than 25% of the domestic market share, and has exported to more than 60 countries. Besides, the high-performance woven products are also exported to more than 80 countries around the world. Attributed to these products and equipment, the companies have earned direct additional sales of RMB 1.357 billion in recent three years.

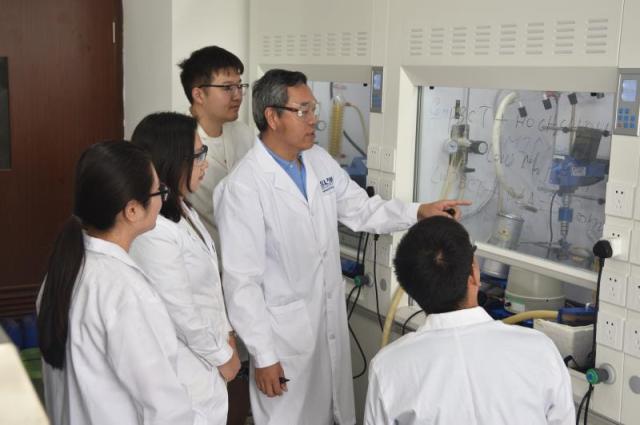

(Team led by Sun Yize)

Turn waste textiles to treasure with high technology

Garbage sorting is now a hot topic in Shanghai and even in China. Then where should waste textiles go? It is estimated that by 2020, the storage of waste textiles will total nearly 200 million tons, while the capacity of renewable spinning will be only 10 million tons. How to turn waste textiles into treasure? Wang Huaping’s team presented the “Chinese Solutions”, which won the second prize of the State Scientific and Technological Progress Award in 2018.

As early as 2004, Wang Huaping began to led his research team to explore the industrialization of waste textiles. Wang was involved in the establishment of technological innovation alliances concerning China’s chemical fiber regeneration and recycling, bio-based fiber and biochemical raw materials, etc., thus promoting the construction of industry standardization system. The physical and chemical method of polyester textiles initiated in the project has made it possible for efficient regeneration of polyester fiber. The production cost of the regenerated polyester has been reduced by 25%, but its performance is still comparable to that of the original polyester.

Today, the project partner companies have built the world’s largest production base of regenerated polyester fiber, producing 300,000 tons of waste spinning regenerated staple fiber, 150,000 tons of bottle flakes and regenerated filaments, and 75,000 tons of low-melting-point/regenerated polyester composite staple fiber. The past three years saw unit sales of 7.990 billion yuan and foreign exchange earning of 261 million dollars. Besides, 38 invention patents have been authorized, 10 scientific papers have been published and 3 standards have been formulated. The cutting-edge technology is not only widely used in automobile interior decoration, environmentally friendly clothing, etc., but also in anti-cracking, reinforcement and isolation of cross-sea bridges, water conservancy dams, highways, buildings, etc.

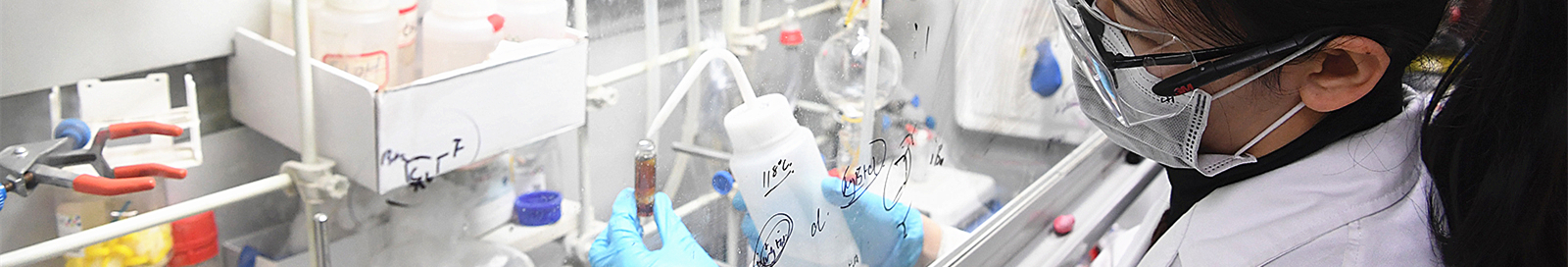

(Wang Huaping’s team carries out scientific research)

Apply DHU technologies in daily life

In recent years, there is a growing number of environmental pollution events caused by excessive indoor formaldehyde, which are harmful to human health. In this case, how to remove formaldehyde becomes a hot topic in decoration and other industries.

Instead of activated carbon, the nano-manganese and non-photocatalytic aldehyde-removal material developed by the team led by Ding Bing can not only directly decompose formaldehyde into carbon dioxide and water, but also has a service life longer than that of other products. It is low in cost and high in aldehyde removal efficiency, up to 97%. The scale production of this material has allowed our alumni companies to achieve sales of more than 10 million yuan this year alone.

Among the DHU achievements shown at the CIIF, there are also others that have been applied in our daily life. For example, the composite material comprising new halogen-free flame-retardant fast curing epoxy resin and glass fiber, developed by Wei Yi’s team, has now been successfully applied to the mid-ceiling of the carriage of Fuxing high-speed train. The health-care and moisturizing soil-releasing finishing agent, developed by Min Jie’s team, has been applied in the fields of knitted underwear, shirts and home textiles. A new type of domestic sewage treatment system for the future, developed by Yang Bo’s team, can help achieve multiple purposes such as high-quality water discharge, energy recovery and resource reuse.

(DHU booth attracts many visitors)

Furthermore, it is worth mentioning that the booth this year features the concept of green environmental protection. Based on the removable exhibition equipment, Associate Professor Hu Jieming from the Fashion • Art Design Institute of Donghua University led students to adopt green environmental protection materials to design the corresponding style of assembly module. The standard exhibition equipment commonly used in Europe and America and the new reusable environmental protection exhibition system with aluminum frame, together with dust-free and odorless construction and exhibition process, are in line with the green concept of contemporary display design.