It is with great pleasure that we introduce the inaugural ofAdvanced Fiber Materialsjournal. Advanced fiber materials is a peer-reviewed, international and interdisciplinary journal published bySpringer Nature Publisher. Our aim is to provide a frame work for research focused on fiber and fiber related expanse, providing a platform for academic experts and scholars to contribute and exchange scientific knowledge. Welcome all. The first issue for 2019 can be downloaded free of charge onhttps://link.springer.com/journal/42765

The cover of Advanced Fiber Materials

Description Papers

The content of the journal reflects the rapid progress and development of the fiber materials with high level papers in the field.Advanced Fiber Materials is launched in 2019 by State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, Donghua University (China) and published by Springer Nature. Accepted article types include Research Article, Review, Letter, News, Perspective and Highlight.

The first issue consists of editorial article, two review articles and three original research papers.

This article outlines the purpose and the scope of theAdvanced Fiber Materials journal. It also introduces the editorial board members of theAdvanced Fiber Materials journal.

Advanced Fiber Materialseditors (from left to right): Editor-in-chief: Prof. Meifang Zhu, Donghua University, China. Associate editor: Prof. Takeshi Kikutani, Tokyo Institute of Technology, Japan. Associate editor: Prof. Tianxi Liu, Donghua University, China. Associate editor: Prof. Seerem Ramakrishma, National University of Singapore. Associate editor: Prof. Guangming Tao, Huazhong University of Science and Technology, China.

Abstract

In this review, Shi et al. (from Nanyang Technological University, Singapore and Donghua University, Shanghai, China) look into the significant progress on flexible fiber-shaped multifunctional devices, including fiber-based energy harvesting devices, energy storage devices, chromatic devices, and actuators are discussed. Particularly, the fabrication procedures and application characteristics of multifunctional fiber devices such as fiber-shaped solar cells, lithium-ion batteries, actuators and electrochromic fibers are introduced in detail. Finally, authors provide the perspectives on the challenges and future development of functional fiber-shaped devices.

Advanced functional fiber and smart textiles

Abstract

In this review report Huang et al. (CQM-Centro de Química da Madeira, Universidade da Madeira, Campus da Penteada, Portugal and Donghua University, Shanghai, China) summarize the recent progresses in the preparation, performances and applications of hybrid nanofibers as drug delivery vectors for antibacterial and antitumor therapy, and as nanofibrous scaffolds for bone tissue engineering or other types of tissue engineering applications. Nanofibers doped with various types of inorganic nanoparticles (e.g., halloysite, laponite, nano-hydroxyapatite, attapulgite, carbon nanotubes, and graphene, etc.) are introduced and summarized in detail. Future perspectives are also briefly discussed.

Preparation and application of electro-spun organic-inorganic hybrid nano fibers

for drug delivery and tissue engineering applications.

Abstract

In this research article, Yan et al. (from Wilson College of Textiles, North Carolina State University and West Virginia University, USA) synthesize a novel PEO based cross-linked polymer (CLP) as the polymer matrix with naturally amorphous structure and high room-temperature ionic conductivity of 2.40 × 10−4 S cm−1. Li0.3La0.557TiO3 (LLTO) nanofibers are incorporated into the CLP matrix to form composite solid electrolytes, achieving enhanced ionic conductivity without showing filler agglomeration. The high content of Li-conductive nanofibers improves the mechanical strength, ensures the conductive network, and increases the total Li+ conductivity to 3.31 × 10−4 S cm−1. The all-solid-state Li|LiFePO4 batteries with LLTO nanofiber-incorporated CSEs are able to deliver attractive specific capacity of 147 mAh g−1 at room temperature, and no evident dendrite is found at the anode/electrolyte interface after 100 cycles.

Schematic diagram of compound solid electrolyte.

Abstract

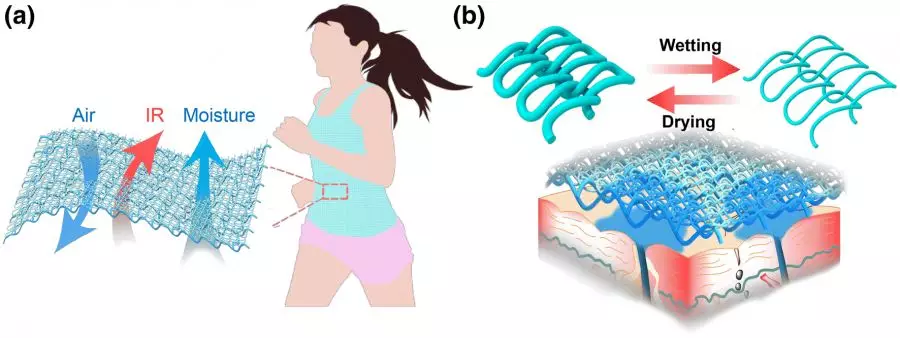

In this article, Hu et al. (from University of Maryland and University of Delaware Newark, USA) design a fabric capable of both sweat- and cooling-management using a knitted fabric featuring a bilayer structure consisting of hydrophobic polyethylene terephthalate and hydrophilic cellulose fibers to simultaneously achieve high infrared (IR) transmittance and good thermal-wet comfort. The IR transmission of this cooling textile increased by ~ twofold in the dry state and ~ eightfold in the wet state compared to conventional cotton fabric. When the porosity changes from 10 to 47% with the comparison of conventional cotton fabric and our cooling textile, the heat flux is increased from 74.4 to 152.3 W/cm2. The cooling effect of the cooling fabric is 105% greater than that of commercial cotton fabric, which displays a better thermal management capacity for personal cooling. This bilayer design controls fast moisture transfer from inside out and provides thermal management, demonstrating high impact not only for garments, but also for other systems requiring heat regulation, such as buildings, which could mitigate energy demand and ultimately contribute to the relief of global energy and climate issues.

Schematics for self-adjusting cooling textiles for sweet and cooling management;(a) Double layer design for good human body IR transmission, moisture transport and air ventilation. (b) Reversible loop structure change during wetting and drying of moisture responsive yarns.

Abstract

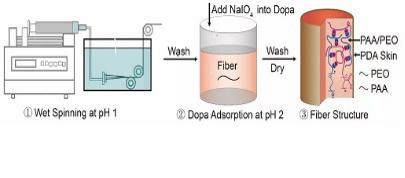

In this research work Li et al. (from Donghua University, Shanghai, China and Georgia Tech., USA) design a multifunctional fiber by incorporation of different components to optimize its performance. The combination of the poly (acrylic acid) (PAA) and poly(ethylene oxide) (PEO) through hydrogen bonding endows the fiber with high elasticity and repairability. Polydopamine (PDA) significantly increases the stability of the fiber, thus the fiber will not dissolve in alkaline solutions and still keep the repairable ability. The fiber shows a reversible swelling-shrinking property as pH values go up and down. Further, the conductive component, carbon nanotube, is adsorbed at the swelling state and then is fastened with fiber shrinking.

Schematics for preparation of PAA/PEO-PDA fiber

Authors do not need to pay anything for publication. All content published in Advanced Fiber Materials in 2019 and 2020 are freely available online vialink.springer.com during these two years.

The authors are kindly invited to submit their paper to Advanced Fiber Materials via the Editorial Manager system (https://www.editorialmanager.com/afms/default.aspx)