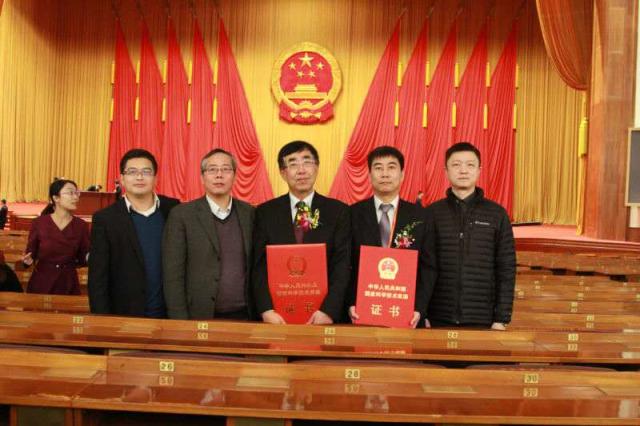

On January 9, the 2016 China’s State Science and Technology Awards Ceremony was held at the Great Hall of the People in Beijing. Top Communist Party of China and state leaders Xi Jinping, Li Keqiang and Liu Yunshan attended the ceremony and presented awards to the winners. Donghua University (DHU) won 4 awards, i.e., 3 second prizes of National Science and Technology Progress Award and 1 second prize of State Technological Invention Award. Chen Ge, Vice President of DHU, together with the winning representatives was present at the ceremony.

(Group photo of DHU representatives and other attendees)

The project of “Key Technologies and Industrialization of PI Fiber Preparation through Dry Spinning” led by Zhang Qinghua, Professor of College of Materials Science and Engineering, won the Second Prize of National Science and Technology Progress Award. For the purpose of dealing with problems such as long production process, high energy consumption of solvent recovery and environmental pollution arising from the method of wet spinning in preparation of PI fiber at home and abroad, DHU team developed the first complete set of technologies and key equipment for preparing PI fiber via dry spinning, and is granted 26 national invention patents. The PI fiber prepared thereby has been successfully applied to heat-resistant filter, special protective garment and other fields, effectively promoting the domestic development of high-performance fiber by leaps and bounds and resulting in significant economic and social benefits.

The project of “Key Technologies and Industrialization of Ecologically Efficient Ramie Textile Processing” led by Cheng Longdi, Professor of College of Textile, is authorized 16 invention patents and leads to the establishment of 2 industrialized production lines, winning Second Prize of National Science and Technology Progress Award. In this project, the team develops the technology of ecologically efficient biochemical one-step degumming, new ramie spinning technology, technology and equipment of long bast fiber spinning and staple fiber spinning, series of special additives and technologies of ramie dyeing and finishing, aiming to solve the problems that have seriously restricted the development of ramie industry such as low labor productivity, severe pollution and low product grade and added value of ramie textile processing. It has been proved that the promotion and application of this project plays a positive role in enhancing the overall technical level of ramie industry and propelling technological progress of the textile industry.

Awarded the Second Prize of National Science and Technology Progress Award, the project of “Key Risk Prevention & Control Technology of Network Transaction Payment System and Its Application” led by President Jiang Changjun is intended to tackle two major technical problems - accurate judgment and instantaneous identification of fraud risk in Internet transaction. With significant technological innovation or breakthrough in interactional analysis of business main bodies, behavior identification of payment system, online certification of system transactions and real-time concurrency of risk control platform, the project team builds a risk prevention & control technology system and platform for network transaction payment system, making the capital loss rate decrease from 3.4/100,000 to 0.97/100,000. In a leading position in the field worldwide, this technology shapes a Chinese shield of Internet transaction security.

The project of “Preparation and Application of New Reactive Dyestuffs with Strengthened Group Function” that Professor Mao Zhiping from College of Chemistry, Chemical Engineering and Biotechnology was involved in was given Second Prize of State Technological Invention Award. The 14 new reactive dyestuffs subject to independent R&D by Donghua University perform quite well in fixation rate on cotton fiber, safety and environmental friendliness in production and use and have passed the safety assessment by National Center of Quality Supervision and Inspection for Dyestuff. Furthermore, the dyestuffs obtain 10 state invention patents with an output of over 13,000 tons.