In the evening of September 15, Tiangong-2 Space Lab successfully blasted off from Qiuquan Satellite Launch Center. Do you know that two scientific and technological results from Donghua University have been incorporated into the launch of Tiangong-2? Donghua wisdom and power successfully serve the national aerospace cause.

One of the results is the “Fiberglass Grid for Semi-Rigid Battery Substrate” developed by the R&D team from the College of Textile, the other pertains to the design of clothing for astronauts by the Fashion • Art Design Institute.

Upgrade of “Fiberglass Wing” of Tiangong

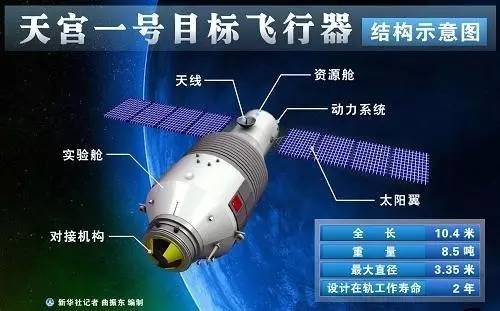

The instant when the solar panels are unfolded witnessed the successful launch of Tiangong-2. It is hard to imagine that the high-performance battery slice of the solar “wing” is attached to fiberglass and was woven into semi-rigid gridding material by Prof. Chen Nanliang’s research team from the College of Textile, constituting the energy source for Tiangong-2.

Early in 2011, the scientific & technological result made by the team played a key role in the smooth launch of Tiangong-1. This time, the semi-rigid fiberglass gridding material employed for Tiangong-2 is an updated version, i.e., version 2.0.

According to Professor Chen Nanliang, the upgrade primarily refers to the manufacture equipment, including the shogging mechanism that determines pattern structure of gridding material, let-off mechanism for uniform delivery of warp yarn and knitting mechanism for connection and sleeving of coils.

Such transformation shall never be underestimated. The manufacture machine and process play a decisive role in making the fiberglass gridding material firm and tough enough to withstand the extreme outer space environment.

A range of improvement and optimization of machine and process significantly enhances the accuracy, strength and stability of the semi-rigid fiberglass gridding material applied to Tiangong-2. For instance, the fabric defects are declined to one defect every 10 meters from the original one defect every 3 meters, and the overall strength improves by 10%, thus powerfully ensuring the success of Tiangong-2 mission.

“Textile is of Great Benefit to National Welfare and the People’s Livelihood”

Although the concept of modern textile has been raised for many years, it seems that “dressing and weaving” is the overall cognition of the common people as to textile. To this, Prof. Chen said, “there is far too much for textile to do to the welfare of the country and people.”

From the successful launch of Tiangong-1 and Tiangong-2 to “Satellite-Borne Antenna Metal Mesh” applied to BeiDou Navigation Satellite to the service for “Tianzhou” cargo spacecraft, Prof. Chen’s research team has always borne in mind and adhered to the “original intention” of Donghua textile people, unswerving and confidently serving the state’s major strategic development.

“China’s textile technology has joined the first-rank around the world, but applications in areas other than the aerospace still remain few. In future, we will constantly explore and expand the application prospects of textile in other industries, giving full play to it for the country and the people.”

R&D Achievement of Clothing for Astronauts Will Be Unveiled

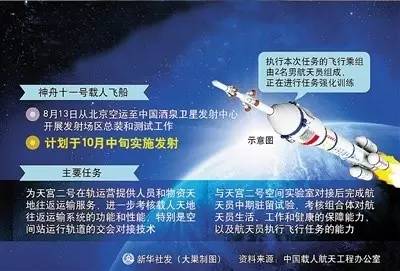

In addition, what else on the journey to the outer space along with Tiangong-2 is the design achievement of clothing for astronauts by the team from Fashion • Art Design Institute.

It is reported that this achievement will be applied to the mission of “Tiangong-2” and “Manned Shenzhou 11 Spacecraft” in Mid October. For more information, please consult the official WeChat of Donghua University – DHUers.