Today, the 2019 National Science and Technology Award Conference was held in the Great Hall of the People in Beijing. The project “Key Technologies and Industrialization of Textile Fabric Color Digitization” by Professor Zhang Ruiyun’s scientific research team from the College of Textiles of DHU won the second prize of the National Science and Technology Progress Award.

This technology solves global problems in the textile industry

The color has a digital “ID card” recognized worldwide

An introduction of Professor Zhang Ruiyun and his scientific research team from the College of Textiles of DHU, winner of the Second Prize of the 2019 National Science and Technology Progress Award

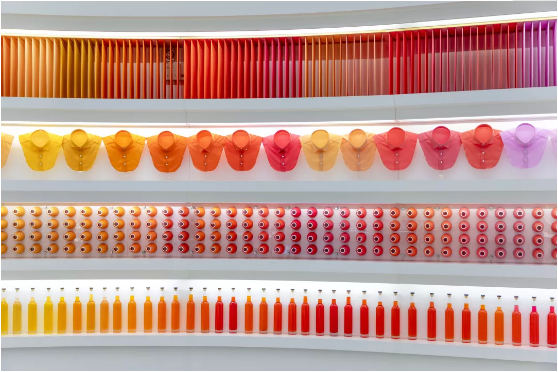

Chinese Red, Tiffany Blue, and Starbucks Green...These well-known colors play an important role in consumers’ awareness for brands. For textiles, color is one of the core elements to express individuality and transmit fashion culture. Color application, its quality control and communication are ubiquitous in the entire textile value chain. However, in textile design and production, how to achieve efficient and precise control of the fabric color and its digital transmission and communication was a major global problem.

The project “Key Technologies and Industrialization of Textile Fabric Color Digitization” by Professor Zhang Ruiyun’s scientific research team of the College of Textiles of DHU, which has injected new energy into the textile industry with color digitization technology, and helped complete the intelligent transformation and upgrading of the textile industry, won the second prize of the National Science and Technology Progress Award.

There are hundred kinds of white? Color digitization is necessary

Color digitization, just as its name implies, is to use data to give color an ID recognized worldwide, like the “ID card” of color. Professor Zhang Ruiyun told the reporter, although the color is visible, it is difficult to precisely distinguish it with the naked eye, and it cannot be accurately expressed in words. For the same fabric, different people will have different perception of its color. The material and organizational structure of the fabric also have a dramatic effect on its color. During the interview, Professor Zhang pointed to a white down jacket worn by the reporter and said that although white is the “simplest” color, there are hundred kinds of white due to different spectral reflectance, which makes the textile enterprises unable to accurately distinguish it.

As a big country of textile production, China’s annual output of textile fabrics has reached more than 100 billion meters. However, in the fabric development of enterprises, the expression of color largely relied on workers’ rich experience. As artificial color matching and physical sample testing were needed, the fabric development cycle was often as long as seven to eight days. Moreover, there was a lack of scientific control of the color.

Professor Zhang Ruiyun (first from right) instructing students to do experiments

In the face of this prevalent problem in textile enterprises, Zhang Ruiyun showed the boldness of northerners and acted at once. She began to carry out scientific research in the field of fabric color matching and simulation. Seven years have passed since 2012. During this period, Professor Zhang Ruiyun’s team conducted exploration and research from the source, independently developed the reflection spectrum system and high coverage gamut system of full spectrum dyes, created the spectrum matching model of mixed color and monochrome, and ensured that the mixed color samples are highly matched with the monochrome fabrics. As the saying goes, where there is a will, there is a way. The accurate color matching technology of yarns and fabrics developed by the team not only realizes the prediction of the fabric color, but also improves the accuracy of the sample color matching by more than 95%. From then on, the color matching no longer depends on workers’ experience and it moves towards intellectualization.

Use big data to create a cloud platform of textile fabric

Complete intelligent search and image simulation by one click

The project “Key Technologies and Industrialization of Textile Fabric Color Digitization” originated from a perfect industry-university-research cooperation. Based on the advantages of textile specialty of DHU, Professor Zhang Ruiyun’s team has joined hands with Lutai Textile Co., Ltd., a world-famous high-end yarn dyed fabric manufacturer, to solve the difficult problems in the production process of textile enterprises, enhance the leading role of innovation, and strive to find a way of self-improvement of textile products with “hard core scientific research strength” in the global competition.

There is a saying that seeing is believing. Color confirmation and communication are necessary steps in the production process of textile fabric enterprises. With the acceleration of globalization, Chinese textile companies have established R&D institutions and production bases in USA, Vietnam and other countries and regions. How to deliver fabric samples? It is difficult to achieve rapid response by sending samples through EMS, but also difficult to accurately read colors due to regional and equipment differences. When the enterprise asked Professor Zhang Ruiyun to solve this knotty problem of long standing, she took over this important task without hesitation.

Professor Zhang Ruiyun and her students

In order to solve the problem, Zhang Ruiyun divided her time between Shanghai and Shandong, conducted research on the production line in a steady way, corrected the data of laboratory test again and again. The structure, texture, material of fabric and other factors may have an impact on the color simulation and image presentation, so many experimental processes are composed of numerous failures. “Professor Zhang’s ‘paranoid’ spirit in leading the team to carry out scientific research work is really admirable,” Xu Lu, a 2017 graduate student majoring in textile materials and textile design, told the reporter. Behind big data is boring and complicated work. Professor Zhang’s rigorous and practical learning attitude affects the people beside her. Under her leadership, the team has overcome the technical bottleneck and developed a high-simulation system which replaces physical processing with virtual samples, solving the consistency problem of color transmission and reproduction of different media fabrics in different places.

Finally, the digital high-efficiency cloud platform of textile fabric built through this project with features of digitization, intellectualization and networking, uses a large database of design information with high restoration and high information capacity to replace physical objects for storage and transmission. It realizes the opening, sharing and collaborative innovation of the resources of textile fabric upstream and downstream industrial chain and cross regional production enterprise as well as the digital transmission of color between the global production plants and important customers, leading to the development of the global industrial chain layout of the textile industry.

Crossover cooperation is the key to win

Realizing the dream of becoming a Leading Textile Power is inseparable from

“technological innovation”

Talking about the experience of winning this award, Professor Zhang Ruiyun summed up their winning secret in one word: crossover. The reporter learned that Professor Zhang Ruiyun was admitted to Donghua University (formerly China Textile University) in 1987. She majored in textile design as an undergraduate. When she was studying for a master’s degree, her research direction was changed to the Clothing CAD. Later, during her doctoral program study period, the research direction further extended to the application of computer graphics and image technology in textile. This interdisciplinary academic background opens up a new world of scientific research for her, which makes her understand both “digitization” and “color”, and finally make her have unique advantages in solving the key technology problems of textile fabric color digitization.

Professor Zhang Ruiyun (fourth from left) instructing students to conduct topic discussion

Professor Zhang Ruiyun humorously said that she is not fighting alone. The university has accumulated rich experience in the field of textile discipline, and the “comrades in arms” from various colleges participating in cross-border cooperation, the enterprises from industry university research cooperation and partner institutions are on the same “boat”. They have the same goal, and make concerted efforts to overcome all contradictions and difficulties. There are many talents in various fields at the university campus. Zhang Ruiyun told the reporter that, “Scientific research has no disciplinary boundaries. In the process of research, interdisciplinary problems need to be solved through cross-border cooperation, and collaborative innovation can break through!” The breakthrough of the key technologies of textile fabric color digitization depends on the technological innovation in the textile field, and it is also inseparable from the innovation in textile dyeing and finishing, textile design, computer graphics and image processing, cloud platform technology, etc. The implementation and industrialization of this technology cannot be divorced from the application and promotion of enterprises.

For the transformation from a leading textile producer to a leading textile power, technological innovation plays a vital role in China’s dream of building a textile power. “The breakthrough of this key technology certainly has given the traditional textile industry characterized by labor-intensive and experienced production a shot in the arm,” Professor Zhang Ruiyun said. There is no end to scientific research. She hopes that this technology could be continuously improved and upgraded, so as to speed up the digital and intelligent development of China‘s textile industry and show the hard power of China’s textile industry to the world.