Masks, protective clothing, antibacterial materials... In just 20 days, a plan of special emergency projects of medical and health protection materials for fighting the epidemic was established, and the products were quickly developed and delivered to the places at the front line of fighting the epidemic. At the beginning of the epidemic outbreak, the State Key Laboratory of fiber material modification, Donghua University (hereinafter referred to as the “Laboratory”), acted quickly to unify national textile and fiber material enterprises and first-line medical units to provide strong scientific and technological support for the development of medical and health protection materials.

Urgent! Complete the emergency project layout in 20 days

On January 28, the fourth day of the Chinese New Year, Zhu Meifang, academician of the Chinese Academy of Sciences and director of the Laboratory, viewed news reports about the epidemic on the way back to Shanghai from her hometown in Jiangsu. “Masks and protective clothing are in short supply, and medical staff are at risk of infection”...as a researcher with more than 30 years of experience in material science, she was burning with anxiety, thinking about how to quickly assemble and match R&D personnel and production forces to fight against the epidemic.

An online director-level office meeting was urgently held to draft a special plan for emergency protection. There was not a second to be lost. After the Laboratory’s WeChat public account posted the “Notice and Guide on the Application of the Medical and Health Protection Material Emergency Project against COVID-19” on February 8, universities, scientific research institutes, textile and fiber materials enterprises, first-line medical units etc., made responses one after another and the national emergency research and development and production forces were quickly launched. More than 70 project applications had been received as of February 16. After project review, classification layout, chain integration, and innovation of project organization, on February 27, a plan of the special emergency research and development projects under the “wartime” was established, and 25 emergency projects were determined based on the optimization principle. Among them, there were 10 key special projects for technical research and application foundation (28 sub-projects), 4 projects for free exploration, 1 project for soft subject, and 10 projects for the popularization of science.

According to the information provided by the Laboratory, these special projects closely focused on the emergency development and production research of the medical and health protective materials against COVID-19, involving masks, protective clothing, antibacterial materials, etc., aiming to make use of the specialty areas of the Laboratory in the field of fiber-based and polymer-based medical protective materials, and organize technical teams to cooperate with enterprises and hospitals for solving key problems in industrialization and realizing emergency production. The discipline chain, the innovation chain, and the industry chain were united to cleave a path. From the organizational form to the fund management, these special projects were implemented under “wartime model”, striving to deliver results at a fast speed.

Difficult! Provide what is urgently needed under the epidemic but not available in China

Through news reports, laboratory researchers learned that protective clothing was stuffy and airtight, and medical staff were uncomfortable to wear them, which made the researchers very worried. “Provide what is urgently needed under the epidemic but not available in China”. Luo Zhangsheng, a graduate of the College of Materials Science and Engineering, has always been maintaining close contact and cooperation with the team of Academician Zhu Meifang in the Laboratory, and they are committed to achieving creative breakthroughs in non-woven fabrics. Luo Zhangsheng, then the chairman of Xiamen Dangsheng New Materials Co., Ltd., received a call from the Laboratory about starting the emergency production of protective clothing. The two parties quickly reached an agreement. Then, he and associate professor Xiang Hengxue, a young backbone teacher of the team, jointly applied for the emergency special project “Structure and performance evaluation of the limited-use one-piece protective clothing made by abrasion-resistant, breathable and high-barrier Dangsheng new material Rowelk®”, striving to produce high-quality protective clothing and deliver them to the places at the front line of fighting the epidemic as soon as possible.

In the absence of workers and raw materials, Luo Zhangsheng tried his best to find a way around it. He managed to submit a sample after three or four days. Dangsheng Company also submitted a petition to the Xiamen Municipal Government, who offered support immediately. With the technical support of the project team, the company immediately entered the “wartime” state of production. By adopting instantaneous pressure release spinning forming equipment, the team developed high barrier, high wear resistance, high moisture permeability safety protection materials, of which some physical and chemical indicators even exceed the “Tyvek” by DuPont of the United States. These safety protection materials were used to produce limited-use medical protective clothing. At present, the daily production of protective clothing of Dangsheng Company is about 2000 pieces. Subsequently, the two parties jointly applied for the high-end protection project urgently launched by the National Natural Science Foundation of China and received special support.

(Rowelk® limited-use one-piece protective clothing produced by the project team and the company)

The project team also donated more than 5000 pieces of Rowelk® limited-time protective clothing to anti-epidemic units at the front line such as Wuhan Fangcang shelter hospitals, Hubei Hanchuan People’s Hospital, the Institute of Infectious Diseases of the Chinese Center for Disease Control and Prevention, Fudan University Shanghai Medical College, as well as cooperators such as New York State Advanced Energy Technology Center and Dresden University of Technology, Germany, which not only solved the problem of the shortage of protective clothing, but also strengthened the anti-epidemic capabilities of international cooperators.

(The project team donating protective clothing to anti-epidemic units at the front line and foreign cooperators)

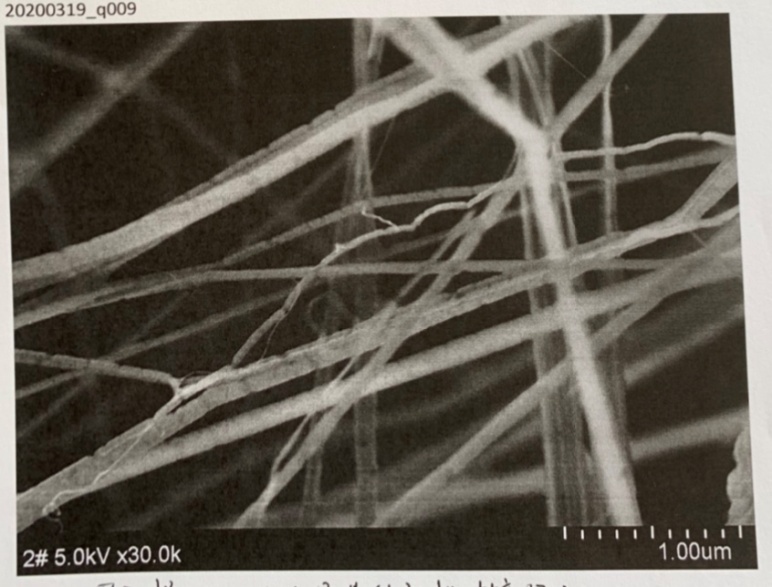

“Boil 5 times” , “Steam once”… there were all kinds of test masks with labels in the office of Professor Li Guang of the College of Materials Science and Engineering, suggesting the busy scene more than a month ago. To ensure the accuracy of data, Professor Li Guang worked as an experimenter and tester between school and home. How to make the mask comfortable and reusable? Base on the emergency project “Research and Large-scale Development of High-performance Protective Textiles and Masks” that she led, the PTFE nanofiber high-performance mask filter membrane (Hypoof) was quickly developed. The fiber can filter very small particles and viruses without electrostatic treatment. The filter membrane made of it is very thin/light, only 1-2g per square meter, with high filtration efficiency, stable performance and recyclability.

(Experimental masks)

(Test scale chart of nanofiber pore size)

The project team cooperated with Shanghai Hanpu New Materials Co., Ltd. to optimize the equipment control and process parameters in emergency. Since the beginning of March, it has produced 150,000 meters of high-performance mask filter membrane (Hypoof), which were supplied to designated mask manufacturers. Shanghai Juchen Baby Clothing Co., Ltd used the filter membrane to produce and sell more than 3 million high-performance protective masks, which were directly supplied to dozens of enterprises and public institutions, providing urgently needed material support during the critical period of resumption of work and production.

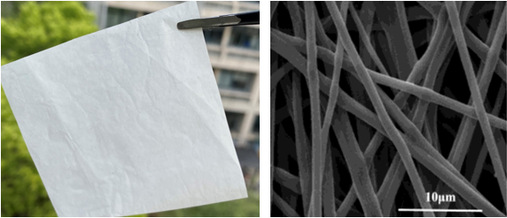

(The Lyocell melt-blown non-woven fabric)

In the special period of “the mask is hard to buy”, those who get melt-blown fabrics could produce masks. Professor Zhang Yaopeng, deputy director of the Laboratory, presided over the project of “Development of All Biomass Multi-stage Antibacterial and Antiviral Protection Filter Materials”. Through process optimization, Lyocell melt-blown non-woven fabrics with diameter and pore size up to several microns can be produced. Lyocell melt-blown membrane has the advantages of raw material renewability, biodegradability, environmental protection of Lyocell process, and good skin affinity, which make it much better than traditional filter materials. It is learned that project in the next stage will focus on the development of a bio-based composite filter material, aiming to achieve multi-level protection against bacteria and viruses.

Heavy responsibilities! It is a mission and more of a normal responsibility

Speaking on the original intention of establishing a plan of emergency special projects under emergency conditions without enough resources, Academician Zhu Meifang said: “the State Key Laboratory must meet the urgent needs and solve the difficulties when the country needs it most. This is our responsibility and mission.” In just more than two months, 25 projects have either achieved mass production, made substantive breakthroughs, or formed forward-looking development layout suggestions. With the joint efforts of everyone, such accountability has become a “normal” of the Laboratory in an emergency period.

In the face of the epidemic of COVID-19, it is particularly important for the public to know how to realize “scientific protection”. It is the responsibility of the Laboratory to speak for it in time and carry out professional science popularization. They guided the public to learn knowledge about protective materials and scientific epidemic prevention through post popular science articles such as “The Shield of the War of Epidemic Struggle: Make You Understand Personal Protective Non-woven Materials”, and “Anti-epidemic Fiber: Micro-Nano Fiber Non-woven Materials in Masks” on the WeChat public account of “SKLFPM”. And Professor Jin Xiangyu, an expert in non-woven materials, participated in the research and development of the emergency special projects. At the same time, he also participated in the drafting and formulation of the group standard “Civil Sanitary Mask” and “Technical Specifications for Children’s Masks”, authored many popular science articles, and published the monograph The Shield of the War of Epidemic Struggle: Make You Understand Personal Protective Non-woven Materials.

(Cover of the monograph The Shield of the War of Epidemic Struggle: Make You Understand Personal Protective Non-woven Materials.)

The global epidemic situation is still complex and grim. Staff of the Laboratory cared about overseas science researchers and sent consolatory letters to more than 30 partner institutions such as Stanford University, Milan Polytechnic University of Italy, MARPOL Research Institute of Germany, Madeira University of Portugal, and over 50 international well-known professors who have cooperated closely with the Laboratory to introduce the emergency special projects of the Laboratory. They also sent masks and protective clothing and other materials to the institutions and experts in need.

(The consolation letter “Sky We Share, Together We Stand”)

After the epidemic, people may still face a long-term struggle with pathogens. In this regard, Academician Zhu Meifang said that this epidemic is like a “final exam” that let us re-understand the meaning of “peacetime and wartime combination”. In the next step, we need to develop more efficient, safe and economic antibacterial and antiviral textiles with extended broad-spectrum, build a collaborative innovation platform of “three integration” of science and education, industry and education, and military and civilian, and establish an advanced manufacturing chain system of material design and fiber molding, so as to comprehensively improve the ability of prevention and control of infectious diseases in China. There is a long way to use science and technology to fight the infectious diseases. DHU’s “National Team” has always been on the way.